How to Use Bivocom Gateway to Obtain Liquid Surface Height via Radar

In today’s era of expanding industrial operations and critical hydrological management, the demand for reliable liquid level data has surged—particularly in environments where heavy rain, thick dust, or extreme temperatures test traditional sensing technologies. Consequently, from monitoring chemical tanks in factories to tracking water levels in remote reservoirs, inaccuracies or failures undoubtedly disrupt operations, compromise safety, or hinder resource planning. Notably, traditional sensors generally falter here, whereas millimeter-wave radar rises to the challenge—a capability fully unlocked by Bivocom Gateway Radar solutions that thereby transform raw radar data into actionable, network-ready insights.

YouTube -Video Tutorial: How to Use Bivocom Gateway to Obtain Liquid Surface Height via Radar

Core Advantages Explained

Precision Radar Technology Overview

This compact sensor, composed of a radio frequency unit, processing unit, and printed circuit board antenna, operates at 80GHz to deliver exceptional precision. Specifically, it offers ±2mm distance accuracy, 1mm resolution, and beam angles as narrow as ±2.75° (RS485 version) to minimize interference. Moreover, its range spans 0.06~40m, and it is compatible with Modbus/text protocols, making it ideal for scenarios from tank level tracking to river hydrology. Furthermore, it performs seamlessly in harsh conditions: -40~75℃ temperatures and 0~95% humidity.

Why Bivocom Gateway?

- Seamless Connectivity: RS485/RS232 ports match radar interfaces, thereby supporting its 200ms data cycle for stable transmission.

- Native Protocol Support: Modbus RTU/TCP compatibility eliminates integration barriers, thus directly parsing radar data (e.g., ±2mm precision).

- Tough Environment Fit: Operates at -35~75°C with durable housing, consequently enduring harsh industrial conditions.

- Smart Processing & Scalability: Edge computing (880MHz CPU) filters data in real time; additionally, 5G/4G/Wi-Fi and security features (VPN, firewall) enable flexible, secure scaling.

What You’ll Need

Before starting, ensure you have:

- 1x Bivocom Router/Gateway(TG463 in this case)

- 1x Millimeter-wave Radar

- 2x Network Cable(For gateway)

- 2x Power Adapters(For gateway and radar)

- 1x Serial Port Cable(RS485, depending on radar model)

- A computer with Modbus Poll software

Step-by-Step Instructions

Step 1: Test the Radar with Modbus Poll

We typically first test the sensor using Modbus Poll whenever the register address or data type remains uncertain, since this preliminary validation ensures parameter accuracy; subsequently, we apply confirmed configurations to the gateway.

- Connect the radar to your computer via the serial port.

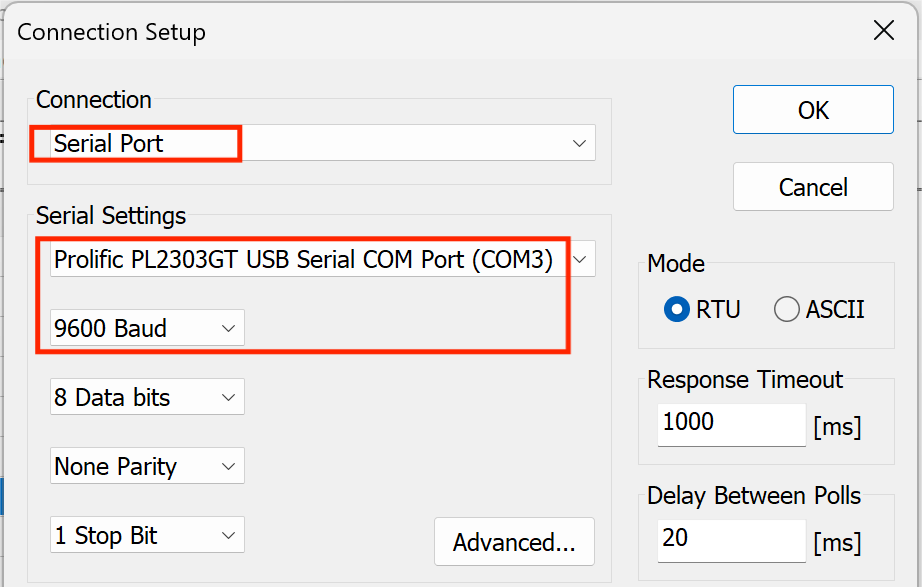

- Set the configuration, “serial Port”, select the correct COM port, set the baud rate to 9600, then click “OK”.

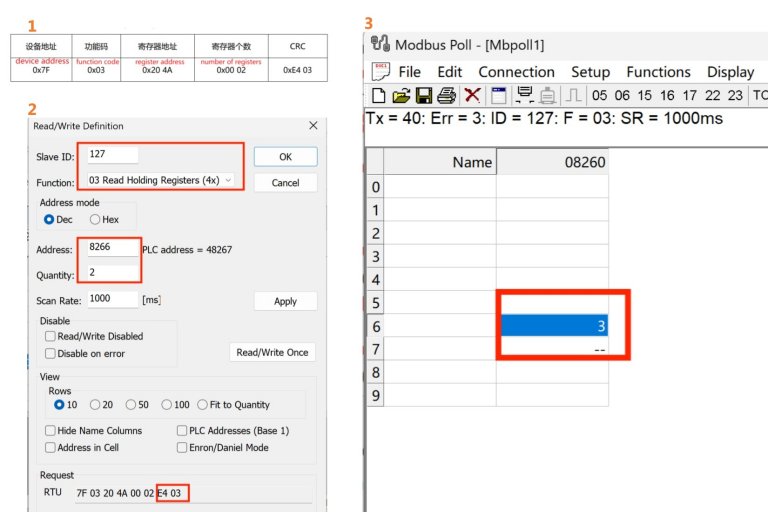

- Set the Read/Write Definition.

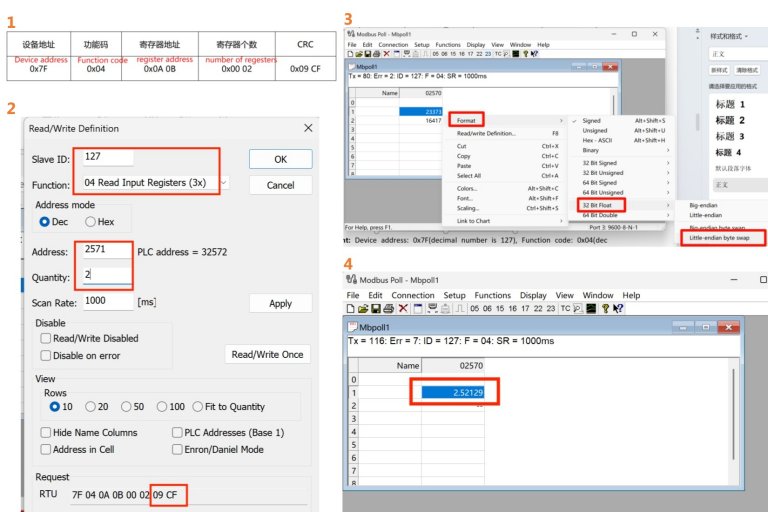

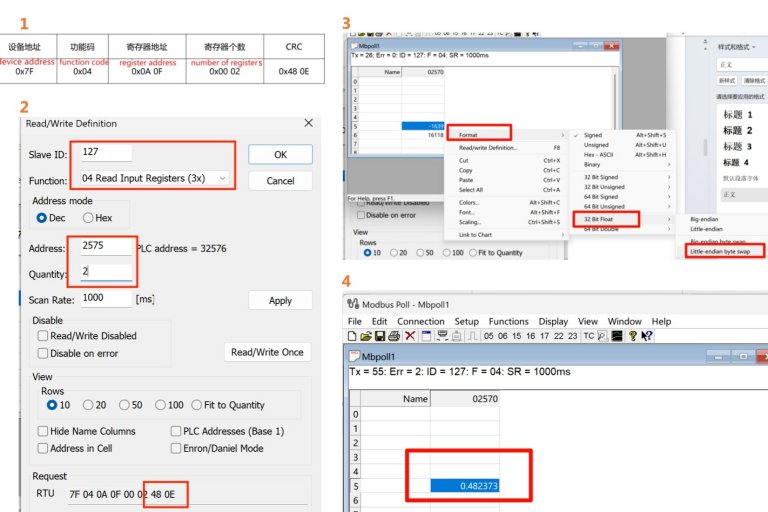

4. Subsequently, test key parameters according to the sensor’s documentation:

- Liquid level: Device address: 0x7F(decimal number is 127), Function code: 0x04(decimal number is 4), Register address: 0x0A 0B(decimal number is 2571), Number of registers: 0x00 02(decimal number is 2). Then ensure correctness through CRC. Change the data type to float (little16) type data.

- Empty height: Device address: 0x7F(decimal number is 127), Function code: 0x04(decimal number is 4), Register address: 0x0A 0F(decimal number is 2575), Number of registers: 0x00 02(decimal number is 2). Then ensure correctness through CRC. Change the data type to float (little16) type data.

- Mounting height: Device address: 0x7F(decimal number is 127), Function code: 0x03(decimal number is 3), Register address: 0x20 4A(decimal number is 8266), Number of registers: 0x00 02(decimal number is 2). Then ensure correctness through CRC. Change the data type to float (little16) type data.

Step 2: Configure the Bivocom TG463 Gateway

Once the radar is confirmed functional, proceed to configure the gateway for data collection and transmission.

- First, access the gateway’s WEBUI (192.168.1.1), then navigate to “Setup” → “WAN”, and proceed to connect to the network (use DHCP in this case).

- Subsequently, go to “Data Collection” → “Basic Setting”, enable data collection, and set the Collect Period and Report Period according to your specific needs. If caching historical data is required, additionally enable the Cache feature and configure the relevant parameters. Once these settings are finalized, click “Save & Apply”.

- Thereafter, navigate to “Interface Setting”, enable COM1 (RS485), set the baud rate to 9600, and specifically select “Modbus RTU” as the protocol. Configure other settings as needed; once all adjustments are complete, then click “Save & Apply”.

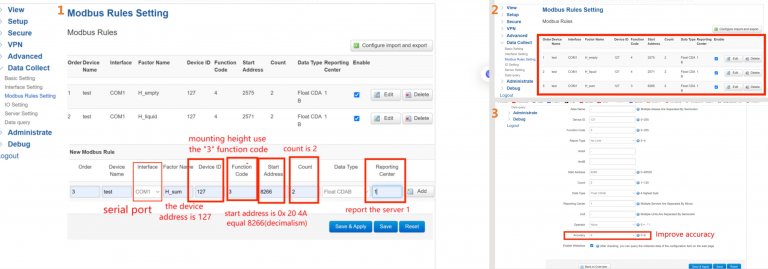

4. Then click “Modbus Rules Setting”, we can know the parameter through the test of Modbus poll.

- H_liquid (liquid level): Device address 127, Function code 4, Register 2571, 2 registers, data type float (little16).

- H_empty (empty height): Device address 127, Function code 4, Register 2575, 2 registers, data type float (little16).

- H_sum (mounting height): Device address 127, Function code 3, Register 8266, 2 registers, data type float (little16).

- Increase precision to 6 digits, then click “Save & Apply”.

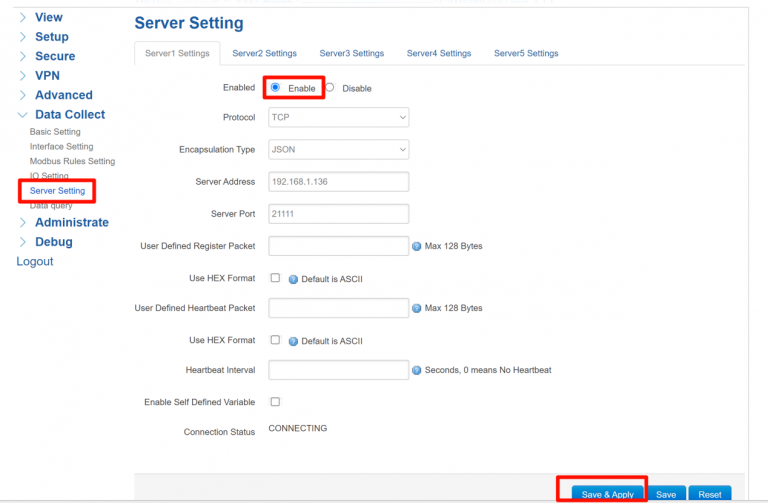

- Click “Server Setting”, enable server 1. In this case, we set the server protocol is TCP, and encapsulation type is JSON. And input the server address and port. Click “Save & Apply”.

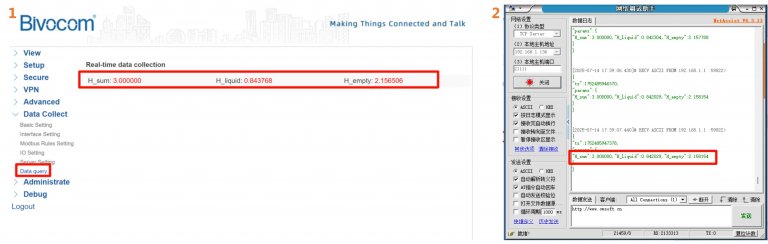

6. Finally, view the result through Network Assistant or WEBUI “Data query”.

Comment