Background

A smart factory is a highly advanced manufacturing facility that utilizes various technologies and automation systems to improve operational efficiency, productivity, and overall performance. There is no doubt that smart factories will become a new form of manufacturing and a new engine for future manufacturing.

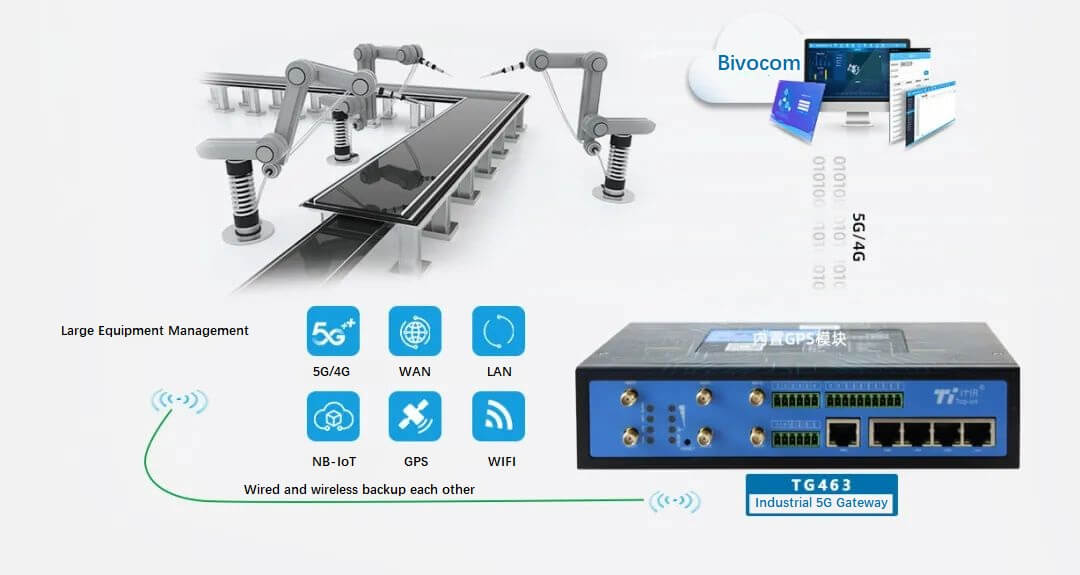

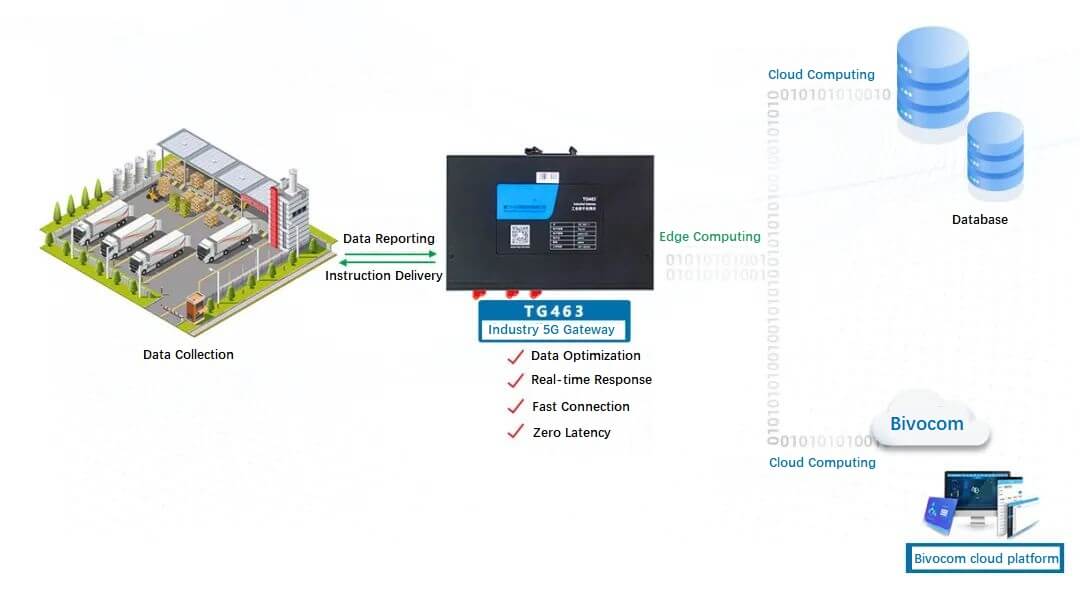

Supported by 5G+ Industrial Internet, Bivocom focuses on intelligent manufacturing and aggregates comprehensive factory data. By leveraging technologies such as digital twins, AI algorithms, 5G, and artificial intelligence, Bivocom has independently developed the 5G Industrial Gateway TG463. It empowers various industries such as intelligent manufacturing, smart grid, autonomous driving, and smart logistics.

Product Description

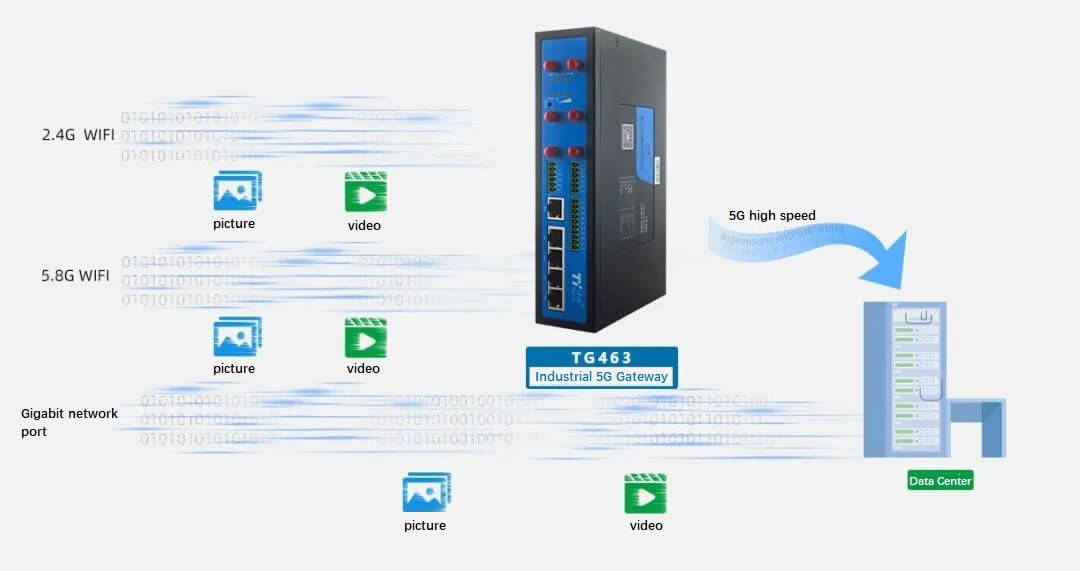

The industrial gateway is one of the important components in a smart factory, which can aggregate, transmit, process, and analyze data collected from different devices. Bivocom TG463 is a 5G industrial gateway that offers high speed, large connectivity, wide coverage, low latency, and high reliability. It supports 4G/5G, wide area network (WAN), local area network (LAN), and WiFi multiple network access, effectively solving the problem of information silos. It meets the comprehensive network coverage requirements of smart factories for the entire production process, supporting various applications such as information collection and production control, and facilitates seamless connectivity in smart factory operations.

Meanwhile, the Bivocom 5G Industrial Gateway TG463 features 5G LAN capabilities, powerful data processing and computing capabilities. It supports local data storage and analysis for decision-making and adopts an open-system design, allowing for secondary development and embedding of third-party SDKs. In terms of material and exterior design, TG463 employs industrial-grade waterproof housing, along with a high protection rating of up to IP66 when paired with waterproof sleeves. This makes it suitable for various industrial environments, both indoors and outdoors. It is not only applicable to smart factories but also finds wide applications in areas such as smart grids, autonomous vehicles, smart cities, intelligent water management, and oil pipelines.

Product Function

Intelligent Management

TG463 integrates cloud computing, big data, 5G, etc., to enable real-time monitoring, collection, and transmission of information data related to production, equipment, and materials in smart factories. It analyzes and processes the uploaded data to achieve refined control and optimization of the production process.

Safety Pre-warning

Safety is of paramount importance for manufacturing companies as it relates to property and personnel security. TG463 supports the installation of signal alarms, which can emit alarm signals in case of emergencies. Simultaneously, it can transmit abnormal data to the platform through 5G and WiFi, etc., enabling precise prevention of accidents.

Quality Inspection

The AI-based quality inspection system utilizes 5G and visual recognition technology. TG463 possesses precise identification capabilities, allowing for efficient and accurate identification of defective products with a low error rate of 3%-4%.

Security Management

By integrating high-definition cameras, TG463 provides comprehensive monitoring of the factory premises, corridors, offices, production lines, and other areas. It enables 24/7 uninterrupted video surveillance and supports alarm-triggered recording. This facilitates real-time monitoring of personnel, equipment, materials, and the environment. The system ensures effectively safeguarding factory security.

Product Advantage

- The digital management of the smart factory production process has been implemented, which improves its production efficiency.

2. Autonomous early warning and fault diagnosis of production equipment can be conducted to avoid the loss of benefits caused by equipment abnormalities.

- Production management and remote monitoring of the smart factory can be carried out anytime, anywhere on mobile devices, enhancing the safety and convenience of the factory.

- Optimization and autonomous control of the production process have been achieved, improving the competitiveness and innovation capability of the factory enterprise.

Comment