Redefining How Industries Monitor Gas Storage

Nitrogen serves as an indispensable resource across electronics manufacturing, food preservation, and chemical processing. However, tanks storing this critical gas carry severe risks: silent leaks may cause suffocation, pressure failures might trigger explosions, and -196°C temperatures threaten workers. Moreover, manual monitoring remains slow, error-prone, and frequently misses early warnings. Consequently, Bivocom’s IoT Nitrogen Tank Monitoring transforms disconnected storage into smart, responsive systems.

IoT Nitrogen Tank Monitoring

The Basics: From Tanks to Smart Sensors

First and foremost, storage tanks are sealed containers for liquids, gases, or solids, widely used in energy, chemicals, healthcare, and food. Nitrogen tanks, in particular, are cryogenic pressure vessels designed for ultra-low-temperature liquid nitrogen (-196°C). They must handle extreme cold (to prevent material brittleness), manage rapid vaporization (1L liquid expands to 696L gas, risking overpressure), and mitigate nitrogen’s suffocation hazards. Moreover, they use double-layer vacuum insulation to reduce evaporation and integrate fast-acting relief valves for pressure control. Ultimately, they balance thermal control and pressure management for safe, efficient storage—foundations that IoT Nitrogen Tank Monitoring builds upon.

The Limits of Traditional Monitoring

How IoT Solves Nitrogen Tank Challenges

Accordingly, IoT technology directly addresses these flaws through real-time sensing, intelligent alerts, and lifecycle optimization:

- Real-Time Sensing: Continuous monitoring of liquid nitrogen temperature (-196°C), external tank temperature, pressure levels, and gas concentration. Consequently, subtle changes are instantly detected.

- Proactive Alerts & Control: Cloud-based dashboards enable remote oversight. Specifically, tiered alerts notify teams via SMS/app during anomalies; additionally, automated pressure releases activate in emergencies.

- Predictive Optimization: AI analyzes vaporization patterns to optimize refills, cutting waste by 30%. Simultaneously, automated logs ensure compliance, while predictive maintenance reduces downtime.

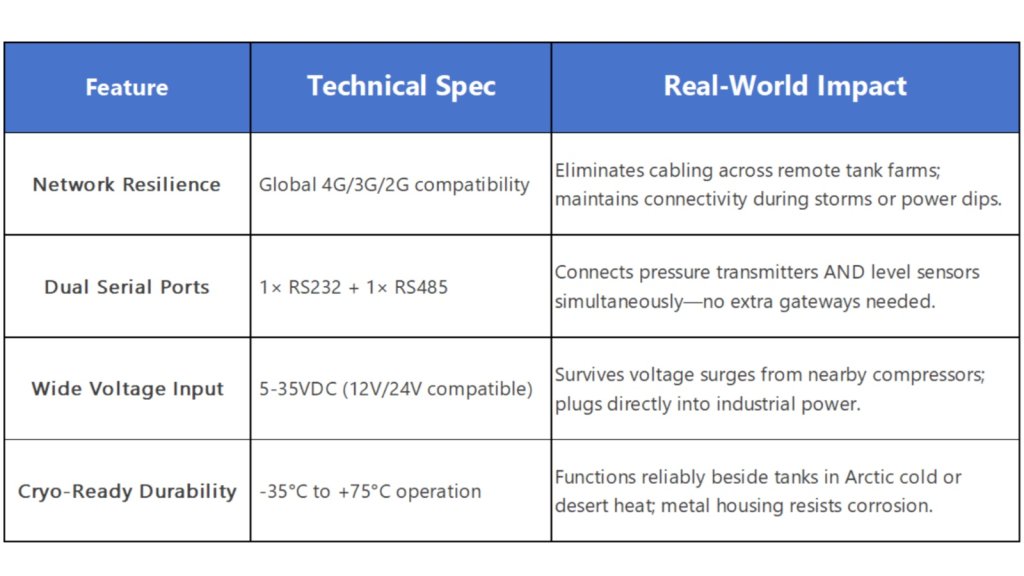

Bivocom TD210: IoT Cellular Modem

Indeed, this rugged 4G modem transforms isolated cryogenic tanks into connected assets. It bridges the gap between legacy sensors and modern cloud platforms—turning fragmented data into unified safety intelligence, which is critical for effective IoT Nitrogen Tank Monitoring.

Notably, the TD210 doesn’t just collect data—rather, it translates it, ensuring cross-generational system interoperability.

- Protocol flexibility: Seamlessly converts sensor data from Modbus RTU to MQTT or Modbus TCP. Consequently, real-time pressure/level readings appear instantly on devices.

- Multi-point data sharing: Simultaneously sends data to 5 destinations (local control rooms, company clouds, suppliers). Therefore, if pressure spikes, all stakeholders are notified immediately.

Field Deployment:From Tank to Dashboard in 3 Steps

To illustrate, let’s walk through a real scenario: monitoring an outdoor nitrogen tank with the TD210. It’s a straightforward process with big results.

Step 1: Simple Physical Installation

Install the TD210 in a weatherproof box near the tank. It teams up with:

- ⚡Power: 12V supply from cabinet (with backup breaker)

- 📡Antenna: High-gain 4G antenna facing nearest cell tower

- 🔌Data: RS485 cable to ADAM-4017 module (collects sensor signals)

In short, this setup is designed for minimal complexity, ensuring that even existing teams can deploy IoT Nitrogen Tank Monitoring without extensive training.

Step 2:Data Flow Architecture & Hardware

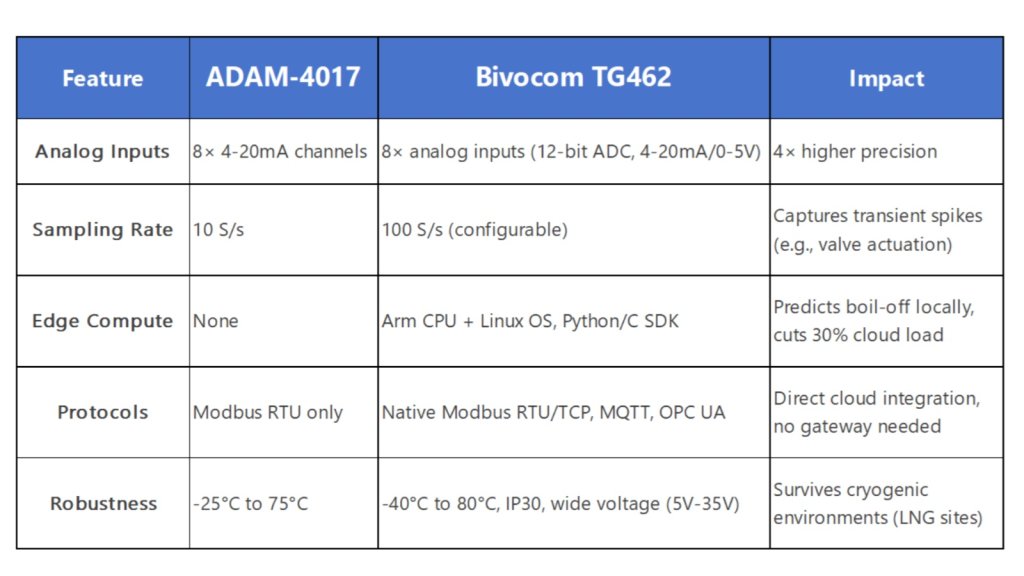

Evolution: From ADAM-4017 to TG462

To begin with, Bivocom TD210 integrates seamlessly with ADAM-4017 systems, operating on a plug-and-play basis—ideal for enhancing existing IoT Nitrogen Tank Monitoring setups without overhauls. Simply connect the TD210’s RS485 port to the ADAM-4017, and it will automatically pick up Modbus RTU data with no extra configuration required. Instead of replacing your current hardware, this solution merely amplifies its capabilities, ensuring continuity in your nitrogen monitoring workflow.

Sensors (pressure, level) send 4-20mA signals to the ADAM-4017, which converts them to Modbus RTU The TD210 picks up this data via its RS485 port. It converts the data to MQTT and sends it over 4G to both cloud platforms and local systems.

Advanced Replacement: TG462 Edge Gateway (Future-Proof)

For those seeking a full, future-proof upgrade, the TG462 Edge Gateway emerges as a powerful replacement for the ADAM-4017. Moreover, it consolidates “acquisition-compute-transmission” capabilities into a single device, streamlining the data pipeline for IoT Nitrogen Tank Monitoring. This all-in-one design not only simplifies hardware management but also equips your system to handle advanced analytics and evolving connectivity needs—ensuring your nitrogen monitoring infrastructure stays ahead of technological shifts.

Step 3: Actionable Insights, Instantly

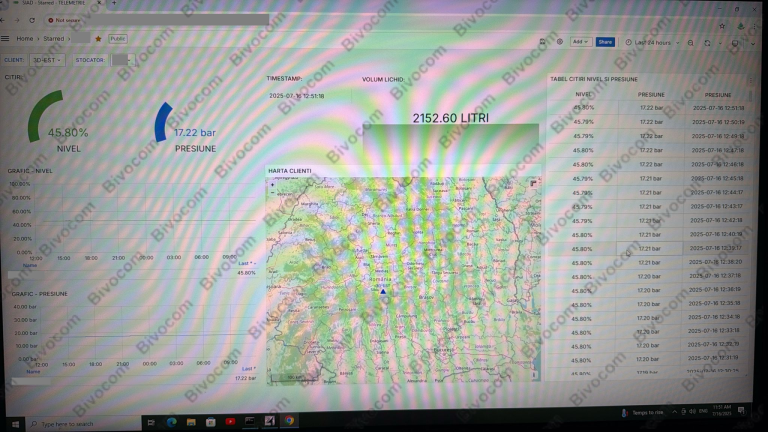

Real-Time Visibility

Concurrently monitor pressure trends, liquid levels, and device status remotely via any web-enabled device. Access live dashboards displaying real-time pressure (bar), tank temperature (°C), and operational status. Subsequently, review 24-hour historical curves with zoom/click functionality for granular data inspection. Furthermore, manage multi-site deployments via centralized geolocation mapping – simply click tank icons for site-specific analytics powered.

Proactive Alerts

Critical pressure alerts (≥18bar) trigger immediate SMS/calls to engineers. Simultaneously, low-level warnings (≤10%) auto-notify procurement teams. Most importantly, AI-driven anomaly detection identifies abnormal patterns (e.g., 10% level drop in 5 minutes), consequently initiating automated diagnostics to pinpoint sensor/connection failures before operational impact.

Intelligent Planning

Automatically generate daily/monthly/annual consumption reports to optimize refill cycles. Concurrently, predictive maintenance algorithms analyze pressure fluctuations and operational duration to preemptively schedule sensor calibrations and insulation integrity checks. Consequently, this prevents unplanned downtime while maximizing asset lifespan.

Future Outlook

The current IoT-driven transformation of nitrogen storage is merely the foundation; advancing technologies will, moreover, further integrate intelligence, efficiency, and security into these critical systems. Key trends, in particular, will shape the next phase of evolution:

- AI Autonomy: Machine learning models will predict evaporation by correlating ambient conditions, usage patterns, and tank longevity. Subsequently, these insights will enable self-refilling systems—thereby eliminating downtime.

- Material-Energy Synergy: Next-gen tanks will integrate lightweight alloys with sensor-embedded insulation; simultaneously, boil-off nitrogen will be repurposed to power on-site devices. Thus, grid dependency will be drastically reduced while enhancing sustainability.

- Quantum-Secure Data: Critically, nitrogen networks will adopt quantum key distribution (QKD) to encrypt sensor data streams. Consequently, pressure readings and safety protocols become impervious to cyber tampering—moreover, this safeguards operations even against future quantum computing threats.

Join the Smart Nitrogen Revolution

With 11+ years of industrial IoT expertise and deployments across 90+ countries, Bivocom empowers your transition—whether safeguarding biobanks, scaling semiconductor fabs, or securing chemical plants. Moreover, we stand at the forefront of IoT Nitrogen Tank Monitoring, delivering solutions that redefine efficiency and safety. Specifically, our offerings include:

- Solution Piloting: Firstly, test real-time IoT Nitrogen Tank Monitoring in your operational environment, ensuring seamless integration with your existing workflows.

- Customized Connectivity: Furthermore, mix 4G, LoRa, and edge computing to build networks that thrive in extreme cold, remote locations, or dense industrial zones. This flexibility, in turn, ensures IoT Nitrogen Tank Monitoring remains reliable regardless of environmental challenges.

- Platform Integration: In addition, unify nitrogen data with your systems via intuitive dashboards, making IoT Nitrogen Tank Monitoring insights accessible and actionable for your team.

Ready to Transform Nitrogen Safety?

Contact [email protected] for a free assessment. With Bivocom, you don’t just upgrade tanks—you join a movement where every nitrogen molecule is monitored, every risk is anticipated, and every industry thrives on smarter storage. After all, IoT Nitrogen Tank Monitoring isn’t just a tool; it’s a cornerstone of modern industrial safety and efficiency.

![[Case Study] Bivocom Smart Pole TG451 & Sensors](https://www.bivocom.com/wp-content/uploads/2026/09/Case-Study-Bivocom-Smart-Pole-TG451-Sensors-768x512.png)

Comment