Revolutionizing Smart Power Management

An electrical panel, often called a distribution board or breaker box—serves as the core hub of power systems. It distributes electricity from the main supply to circuits while providing critical overload/short-circuit protection. It safely routes grid power to end devices (e.g., lights, machinery, HVAC systems) and ensures reliable energy flow for homes, factories, and infrastructure. Essentially, it acts as a traffic controller, directing energy where and when needed.

From Traditional Panels to IoT Smart Panels

Traditional electrical panels face critical limitations. Specifically, their status relies on manual inspections, thus leaving data stale. Moreover, faults are discovered only after occurring, with no early warnings. Consequently, energy optimization lacks actionable insights. However, Bivocom can change this paradigm. By merging power distribution with IoT technologies—sensors, communication modules, and edge computing, they evolve into smart power nodes. Accordingly, they enable real-time monitoring, data transmission, smart analysis, and remote control. Their value lies in boosting reliability, efficiency, and intelligence while enabling precise energy management. This shift drives three pivotal transitions: From Reactive to Predictive, From Isolated to Connected, and From Manual to Autonomous.

The Smart Panel Revolution

- Sensing Layer: Real-time collection of sensor data. Specifically voltage, current, temperature, breaker status, alongside environmental factors like humidity or gas leaks.

- Network Layer: Diverse communication technologies— wired (industrial Ethernet, PLC, RS485); wireless (Zigbee/BLE/Wi-Fi 6, LPWAN like NB-IoT/LoRaWAN); plus hybrid (dynamic paths) and edge gateways (local processing).

- Platform Layer: Edge computing and cloud platforms process data locally and globally, turning raw numbers into insights. For example, predictive alerts for overheating breakers.

Bivocom IoT Electrical Panel Solution

Bivocom, a leader in industrial IoT solutions, specializes in high-quality modems, routers, gateways, and IoT platforms. Our products bridge the gap between devices and data, making smart systems reliable and efficient. When it comes to IoT electrical panels, we don’t just connect—we empower.

Our hardware suite transforms electrical panels into intelligent energy hubs. Specifically, our industrial-grade devices deliver real-time monitoring, predictive maintenance, and seamless integration across diverse environments. Accordingly, below we delve into how our solutions redefine smart power management, using our TN531, TG465, TR341, and TD210 as primary examples.

Bivocom | TN531, TG465, TR341, TD210

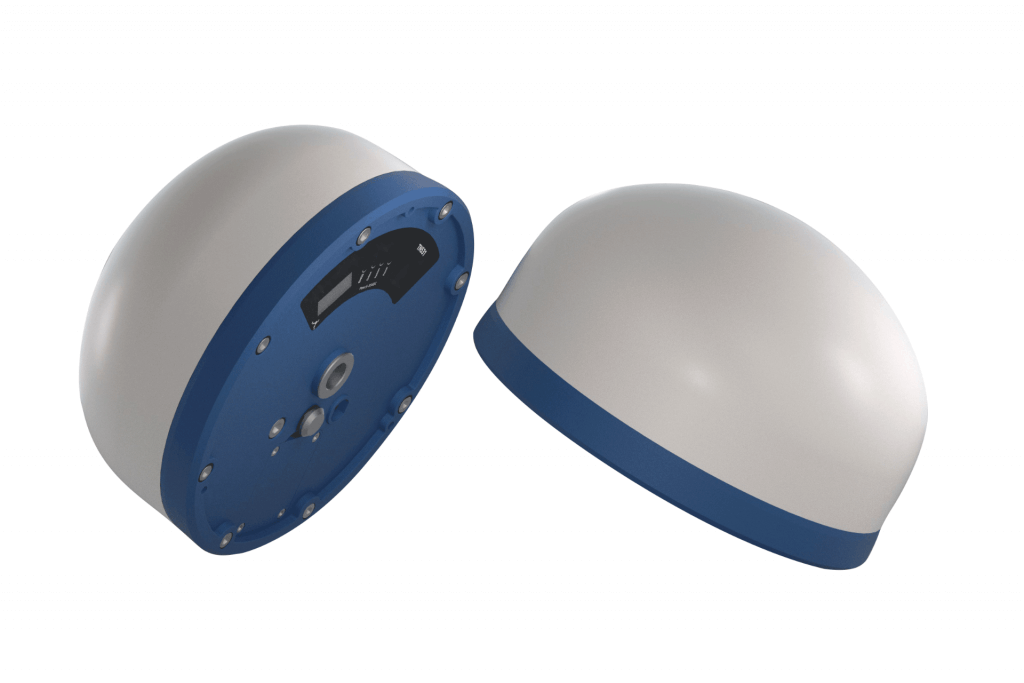

At the core of accurate power system coordination lies precise timing and location data—and the TN531 delivers both. Specifically, this industrial-grade GNSS receiver combines multi-system satellite navigation (GPS, BDS, Galileo) with advanced sensors. Consequently, it achieves sub-millimeter positioning alongside nanosecond-level time synchronization.

- Technical Breakdown: It uses a 6-axis IMU to counteract vibrations or tilts. Consequently, it ensures positioning accuracy remains stable even in dynamic environments like swaying utility poles. With IP68 waterproofing and a wide operating temperature range (-35℃~+75℃), it thrives in outdoor or harsh industrial settings.

- Panel Adaptability: Every event (e.g., breaker trips) receives exact coordinates/timestamps. Consequently, distributed grids trace faults faster by comparing spatiotemporal data. For example, pinpointing a short circuit 800m from Panel A.

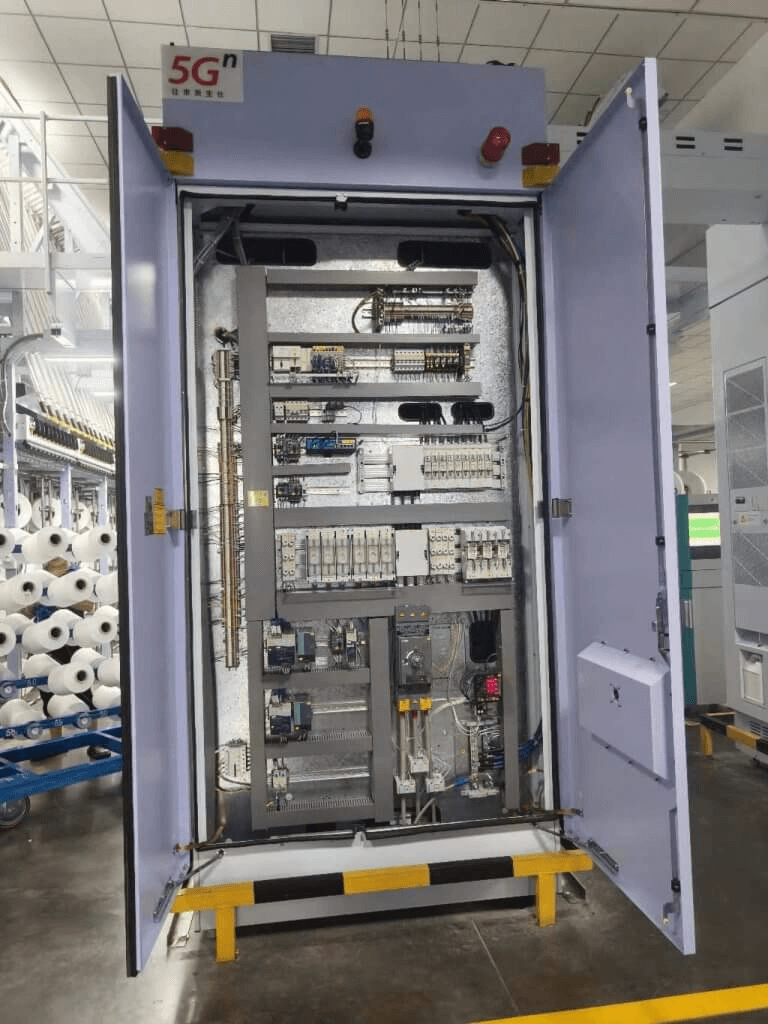

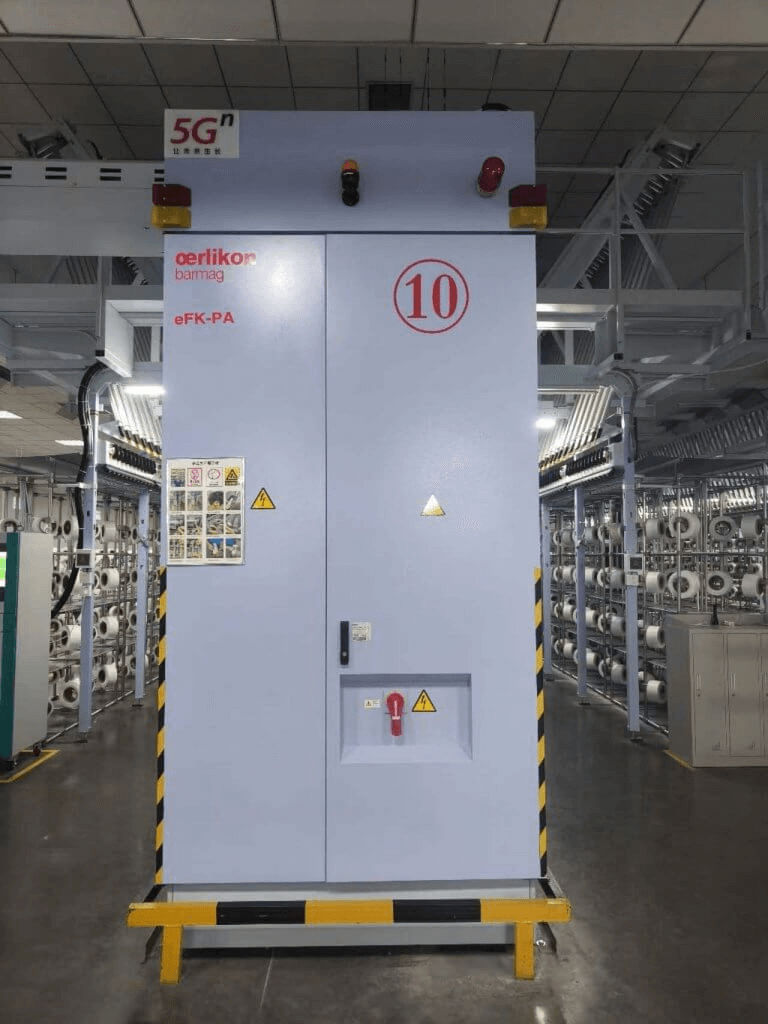

In high-demand scenarios like data centers or factory floors, panels require more than just connectivity—they fundamentally need on-site intelligence. Consequently, the TG465 5G edge gateway acts as a local brain, processing data without relying on distant clouds.

- Technical Breakdown: It is equipped with a 4-core ARM processor and 1 TOPS NPU. Thus, it runs AI algorithms locally. These include predicting current spikes or detecting motor wear, with response times under 10ms. It supports 20+ industrial protocols (including IEC 101/104 for power systems). It also connects to 10+ devices simultaneously via Ethernet, RS485, and digital inputs.

- Panel Adaptability: In industrial main distribution panels, this translates to predictive maintenance: it can flag a bearing failure weeks before it causes downtime by analyzing current, temperature, and vibration data. For renewable energy setups, it syncs solar inverters and energy storage systems, ensuring smooth grid integration.

Stable connectivity is non-negotiable for smart panels, particularly in remote or signal-challenged areas. Accordingly, the TR341 4G router ensures uninterrupted data flow even amid fluctuating network conditions.

- Technical Breakdown: Its dual SIM card design and automatic WWAN/WAN switching guarantee a backup connection. This is critical if the primary network fails. It is especially important for rural photovoltaic distribution areas or outdoor pad-mounted transformers where signal drops are common. It also converts legacy protocols (like Modbus RTU) to MQTT. This lets old meters or breakers communicate with modern cloud platforms.

- Panel Adaptability: Ensures reliable tenant energy data uploads in commercial buildings, avoiding billing disputes. Simultaneously, it tracks mobile assets (e.g., generator trucks) for real-time blackout response.

Not all panels need heavy-duty processing—many fundamentally require a simple, cost-effective way to connect older devices. Specifically, the TD210 modem is designed for this purpose: thereby turning traditional analog equipment into IoT-enabled assets.

- Technical Breakdown: With RS232/RS485 ports, it links legacy devices (e.g., mechanical meters). It converts Modbus RTU to MQTT/JSON for cloud uploads and offers global 4G/3G/2G compatibility. Its compact size fits confined spaces like corridor distribution boxes.

- Panel Adaptability: In retrofitted residential panels, it eliminates manual meter reading by automatically sending usage data to utility platforms. For streetlight control boxes, it monitors lamp status and reports faults via SMS, cutting repair times from days to hours.

How They Work Together

Indeed, these devices cover every smart panel layer: TN531 specifically provides spatiotemporal context; TG465 notably processes data and triggers actions; TR341 chiefly ensures reliable connectivity; meanwhile, TD210 modernizes legacy systems. Moreover, whether in apartments, industrial parks, or even larger complexes, Bivocom’s hardware markedly enables proactive, grid-connected panels.

The Bivocom IoT Electrical Panel solution adapts to diverse scenarios: Notably, in agriculture, it links irrigation systems and power panels to optimize water and energy use. Additionally, in food processing, it enables remote monitoring of production lines, reducing downtime. Furthermore, in smart buildings, it coordinates HVAC and power distribution to cut energy waste by 15-20%. Ultimately, everywhere, it turns reactive management into proactive control.

The Future of Bivocom IoT Electrical Panel

Bivocom IoT Electrical Panel fundamentally transforms power management. Specifically, it unites precision (TN531), intelligence (TG465), reliability (TR341), and accessibility (TD210). Consequently, it turns electrical panels from passive distributors into active, connected hubs. Thereby, these hubs significantly boost efficiency, cut costs, and enhance safety.

Looking ahead, the future of IoT electrical panels will focus on three trends:

- Material Innovation: Graphene-based components and solid-state breakers will extend lifespans while significantly improving safety. Simultaneously, self-powered sensors will reduce wiring needs, thereby simplifying installations.

- AI-Driven Systems: Digital twins and advanced AI will enable real-time energy simulation. This lets panels predict and adjust to demand before issues arise.

- Universal Connectivity: Moreover, energy routers will seamlessly integrate solar, storage, and electric vehicle charging. Ultimately, this convergence, in essence, creates a unified green energy ecosystem.

Join the Smart Power IoT Revolution

Bivocom’s

11+ years of industrial IoT expertise—indeed trusted across

90+ countries. Notably, whether you’re upgrading legacy electrical panels, optimizing energy distribution in factories, ensuring stable power in remote areas, or integrating renewable energy systems, we partner with you and thus turn electricity management into a seamless, intelligent process. To this end, collaborate with us through these approaches:

- Solution Piloting: Test real-time monitoring and fault response in your specific environment. This includes commercial buildings to rural photovoltaic sites.

- Customized Connectivity: Build panel networks tailored to your needs. Mix 5G, 4G, and LPWAN technologies for reliable data flow.

- Platform Integration: Unify power data on our IoT platform with intuitive dashboards. This makes energy trends and alerts easy to act on.

Ready to Transform Power Intelligence?

Contact [email protected] , indeed, for a free smart panel IoT assessment. With Bivocom IoT Electrical Panel Solutions, you gain more than tools—notably, you join a shift. This shift, in essence, is toward efficient, secure, and self-healing power systems. When electrons move, our tech tracks. When data sparks, smarter energy grows.

-1024x576.jpg)

Comment