Bivocom’s TG451 | Transforming Food Processing with Secure VPN Remote Control

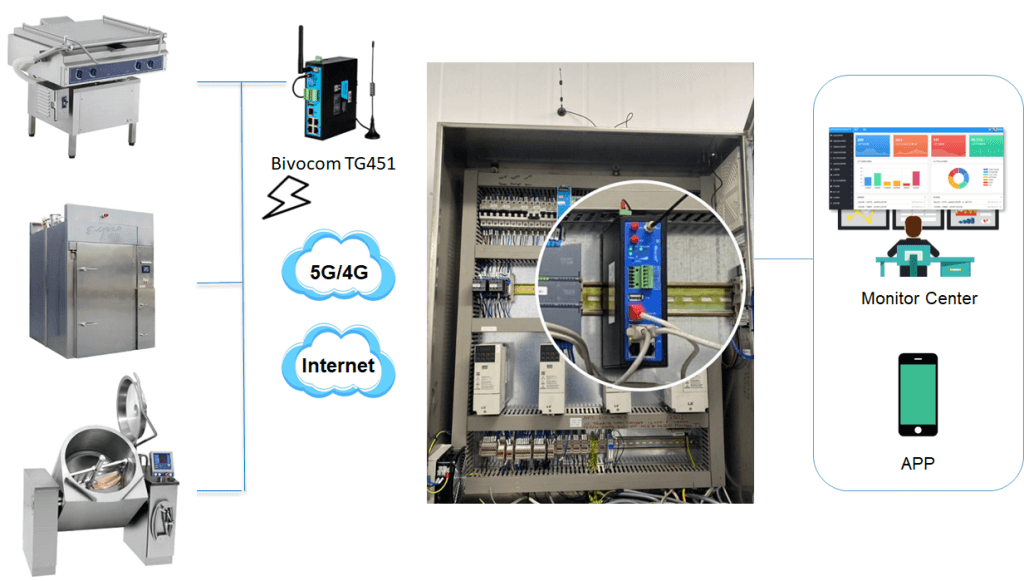

Food processing and packaging lines rely heavily on Siemens PLCs to manage critical equipment like mixers, ovens, and fillers. Ensuring efficiency, hygiene, and minimal downtime is critical for bakeries, dairy plants, and meat packers worldwide. However, traditional onsite management of these PLCs often leads to delays, security vulnerabilities, and operational inefficiencies. Thankfully, Bivocom’s TG451 industrial gateway offers a streamlined solution: secure VPN remote control that empowers engineers to monitor and adjust PLCs from anywhere. For example, imagine resolving an oven temperature issue or optimizing packaging settings without stepping foot in the factory.

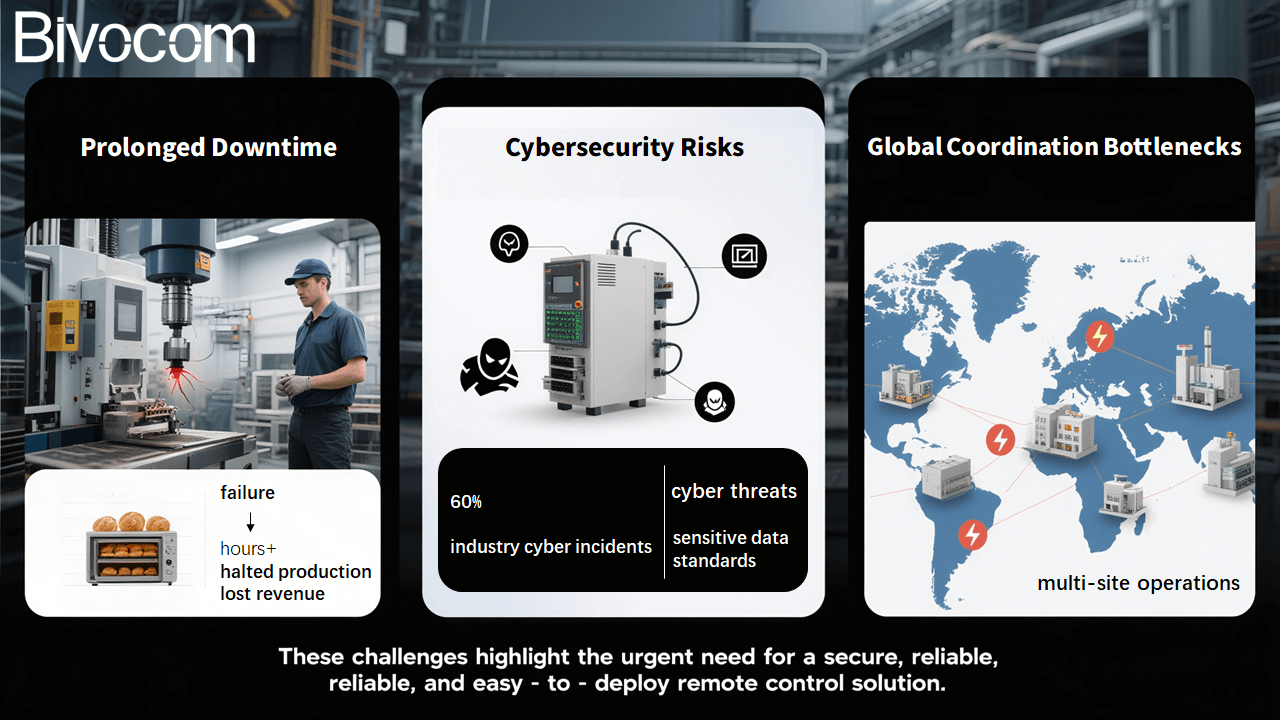

Food manufacturers face three significant hurdles with conventional PLC management:

- Prolonged Downtime: A malfunctioning sensor or misconfigured machine requires onsite technicians, often resulting in hours of halted production and lost revenue. For instance, a bakery might lose thousands of dollars per hour due to a single oven failure.

- Cybersecurity Risks: Unsecured internet access to PLCs exposes systems to cyber threats, potentially compromising sensitive production data and violating standards. In fact, 60% of food industry cyber incidents involve unsecured industrial controls.

- Global Coordination Bottlenecks: Multi-site operations struggle with delayed responses across time zones, leading to inconsistent oversight and prolonged issue resolution. Specifically, a multinational brand might take days to address PLC issues in remote facilities.

In short, these challenges highlight the urgent need for a secure, reliable, and easy-to-deploy remote control solution.

The TG451 tackles these challenges with three core capabilities, each enhanced by strategic transition words for clarity:

- Firstly, the TG451 employs IPsec, OpenVPN, and L2TP protocols to encrypt all communication with Siemens PLCs, creating a private tunnel that blocks unauthorized access. This ensures that sensitive data—such as recipe formulas or production schedules—remains protected from cyber threats.

- Moreover, the gateway maintains detailed audit trails of all remote sessions. For example, meat processing plants can use these logs to demonstrate compliance during regulatory audits.

- Secondly, the TG451’s dual SIM module provides automatic network failover. If the primary 4G/5G connection fails, the secondary SIM activates instantly, minimizing downtime in critical processes like bread dough fermentation.

- Furthermore, the gateway’s rugged design (IP30) allows operation in extreme temperatures (-35°C to 75°C) and high-humidity environments, making it suitable for steam-heavy bakeries, cold storage facilities, and washdown zones in dairy plants.

- In addition, LTE CAT 4/6 support enables high-speed data streaming, ensuring real-time alerts for anomalies like unexpected mixer slowdowns or packaging weight discrepancies. As a result, engineers can address issues before they escalate into costly failures.

- Thirdly, the TG451 simplifies integration with Siemens PLCs through native support for Modbus, and TCP/UDP protocols. This means no complex programming is required—simply plug in the gateway to establish communication with both new and legacy PLC systems.

- Notably, its versatile interfaces (1xRS485, 5xRJ45, WiFi) allow connection to a wide range of devices, from mixers and ovens to fillers and conveyor belts. For instance, a snack production line can integrate TG451 with both modern Siemens S7-1500 PLCs and older S7-300 models.

- Finally, edge intelligence capabilities filter non-critical data, reducing cloud overload and ensuring that engineers receive only the most urgent alerts, such as oven overheating or seal failures in packaging lines.

TG451’s secure VPN remote control can deliver tangible operational improvements across diverse industrial landscapes, blending real-time data management with robust connectivity. Here’s how it drives efficiency in key applications:

Challenge: For instance, a bakery operating 50 sites faced 8+ hours of downtime per PLC issue, as sensor calibration errors required onsite technician dispatches.

TG451 Solution:

- With TG451, engineers gained secure VPN access to Siemens PLCs, enabling parameter adjustments in minutes rather than hours.

- Specifically, real-time monitoring of oven temperatures, conveyor speeds, and fault alerts via the gateway prevented costly shutdowns, reducing unplanned downtime by 30%.

As a result, remote diagnostics minimized onsite visits, cutting maintenance costs by 40% and boosting production continuity significantly.

Application: In water utility networks, TG451 integrates with PLCs managing pump operations in remote or hard-to-reach stations.

- For instance, real-time data on water flow rates and pressure levels is streamed to central dashboards. Consequently, operators can proactively adjust pump speeds via VPN, preventing supply disruptions.

- Additionally, the gateway’s dual SIM failover ensures uninterrupted connectivity, even in rural areas with unstable networks, reducing manual inspections by 50%.

Case Study: Making the Pump Station Smart

Application: In electrical grid management, TG451 monitors PLCs in substations to regulate power distribution and equipment health.

- For example, during voltage fluctuations, engineers can remotely reset circuit breakers or adjust transformer settings via secure VPN, minimizing downtime during faults.

- Moreover, the gateway’s rugged design—withstanding -35°C to 75°C—makes it ideal for outdoor substations, ensuring stable operation in extreme climates while maintaining grid compliance.

Case Study:

How to use Bivocom TG451 and PZEM-016 to monitor AC power

Bivocom Helps Indonesia Telcos to Remote Monitor Facilities

Application: Deployed in commercial fleets, TG451 acts as a VPN gateway for vehicle-mounted PLCs controlling engine performance and onboard systems.

- Similarly, real-time data on fuel efficiency, engine diagnostics, and route optimization is transmitted via LTE CAT 4/LTE CAT6. Thus, fleet managers can remotely tweak PLC parameters to improve fuel economy or troubleshoot issues.

- In fact, predictive diagnostics enabled by TG451 can cut maintenance costs by 35% across logistics companies, leveraging remote alerts to address faults before they escalate.

Case Study: 5G/4G IoT Technology Drives Smart Ambulance

Application: In smart city infrastructure, TG451 manages PLCs controlling traffic light timing, pedestrian signals, and fault detection.

- For one thing, during rush hours, operators can use VPN access to dynamically adjust signal timings in real time, reducing congestion by 20% in high-traffic zones.

- On the other hand, automatic fault alerts for malfunctioning lights allow remote diagnostics, eliminating the need for onsite crews to identify issues, thereby speeding up repairs and improving road safety.

Case Study:

Smart Traffic Management: The Bivocom 4G IoT Gateway TG451 in Action

Europe Partner Visits Bivocom to Discuss Cooperation on VMS and Smart Traffic

Universal PLC Compatibility: Native support for Modbus and dual SIM failover ensure seamless integration with all Siemens PLC generations, from legacy S7-300 to modern S7-1500.

Industrial-Grade Durability: IP30 ruggedness and -35°C to 75°C tolerance enable <5% downtime in harsh environments like bakeries or coastal pump stations, supported by LTE CAT 4/6 connectivity.

Enhanced Security Layers: Encrypted VPN tunnels (IPsec/OpenVPN), and preventing data leakage in countries/regions.

Global Industrial Expertise: Trusted globally in food, utilities, and smart cities — deployments worldwide, backed by ISO 9001 certification.

24/7 Localized Support: Regional teams offer real-time troubleshooting and firmware customization to align with unique workflows, from bakery lines to traffic grids.

Innovation-Driven Design: 5G-ready architecture and edge intelligence future-proof operations, enabling seamless upgrades to AI-driven predictive maintenance.

In essence, the TG451 is more than an

IoT gateway; it’s a versatile enabler of

secure,

data-driven industrial control. Whether optimizing

bakery ovens,

stabilizing water supply, or enhancing

smart city mobility, it delivers:

- Efficiency Gains: Reduces downtime by 30–50% across applications, thanks to real-time VPN remote control.

- Cost Savings: Cuts maintenance expenses by 35–40% via remote diagnostics, thereby improving operational profitability.

- Future Readiness: 5G and edge intelligence capabilities prepare businesses for AI-driven innovations, such as predictive maintenance and autonomous system adjustments.

As industries increasingly demand agility and security, TG451 provides the foundation for digital transformation. Accordingly, Bivocom offers:

- Custom Pilot Programs: Test TG451 in your specific workflow with minimal disruption, allowing you to validate ROI before full deployment.

- 24/7 Technical Support: Global teams assist with firmware updates, VPN configuration, and troubleshooting, ensuring smooth operation across multi-site networks.

- Data-Driven Insights: Leverage real-time analytics to track performance metrics, from downtime reduction to maintenance cost savings, tailored to your industry’s unique needs.

Ready to unlock the potential of remote PLC control?

Contact [email protected] to schedule a live demo or request a customized solution brief. Together, we’ll transform your industrial operations—one secure, intelligent connection at a time.

.jpg)

Comment