Smart Site Monitoring Solution

Genset IoT Monitoring is revolutionizing remote backup power management for infrastructure operators. A leading Southeast Asian toll road operator once managed 100+ generators across extensive highways manually. Technicians were dispatched to every site for routine checks, fuel verifications, and maintenance triggers. This reactive model wasted time, budget, and resources. It created operational bottlenecks, risking revenue loss and regulatory penalties. This case study details their digital transformation through Bivocom industrial IoT gateway.

Key Pain Points

The operator’s core goal was uninterrupted toll plaza operation, even during main power failures. This relied on the readiness of a large, geographically dispersed genset fleet. Legacy manual processes caused major challenges:

- High Operational Costs: Monthly generator run-up checks and similar tasks consumed massive labor hours and travel budgets.

- No Real-Time Visibility: Management had no insight into live fuel levels, battery health, or run-hour status at remote sites.

- Reactive, Delayed Responses: Maintenance was calendar-based or triggered only after failure, increasing downtime risk. Coordinating a response across sites was inefficient.

- Data Silos: Reliance on paper logs and dispersed files made performance analysis and strategic planning nearly impossible.

The business needed a paradigm shift: a unified, smart system to remotely monitor, manage, and maintain all generators from a central location.

Smart Solution: Centralized Genset Monitoring

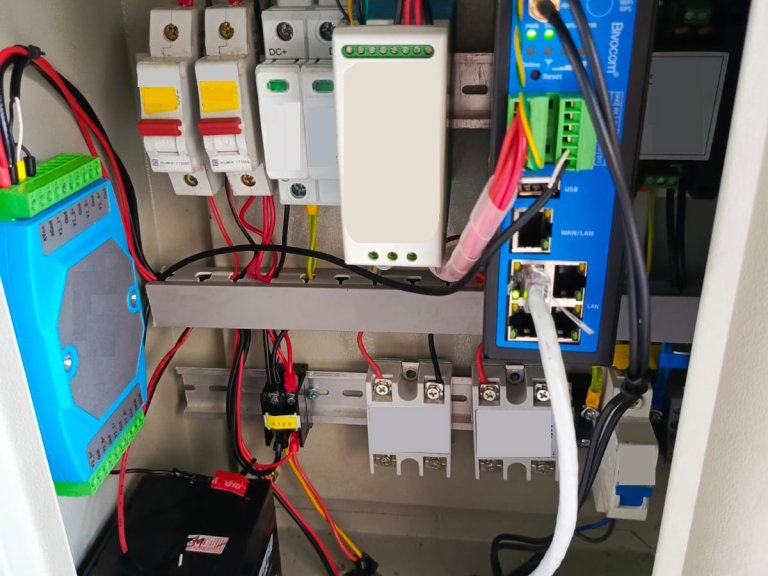

To address these critical pain points, Bivocom’s Smart Site Solution leverages the TG451 as its core. This solution provides complete operational visibility and reliable remote control for critical power infrastructure. It bridges the gaps in manual systems, shifting from reactive, costly site visits to proactive, data-driven oversight.

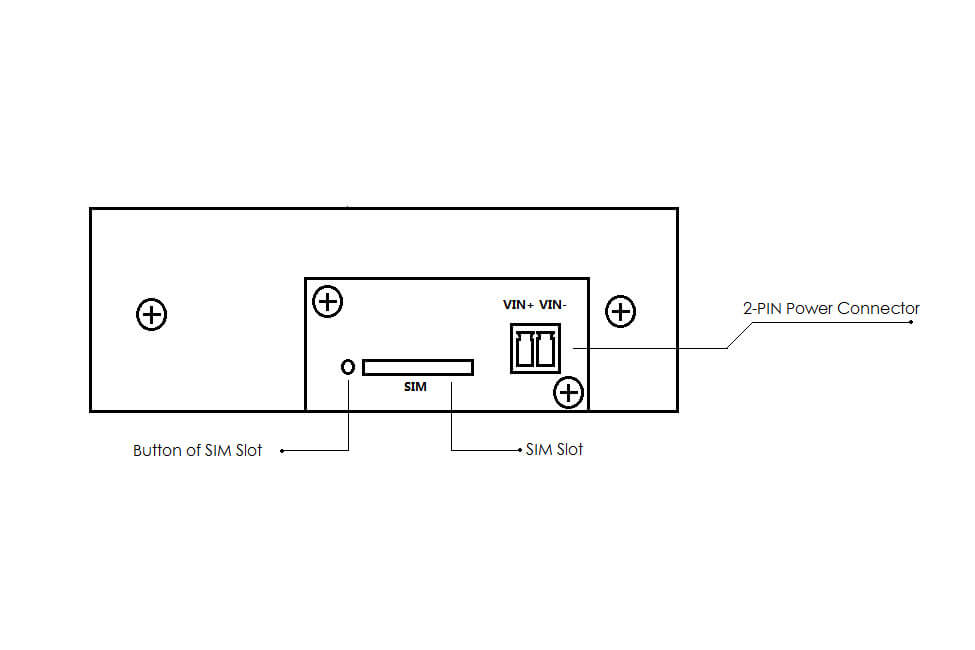

Core Product: TG451 Industrial IoT Gateway

Bivocom TG451 is a programmable industrial IoT gateway built for high‑speed, mission‑critical operations. It combines rugged design, redundant connectivity, and versatile interfaces to collect, process, and transmit field data seamlessly. With support for remote device control, it enables reliable monitoring and management in unattended environments.

- Industrial Durability: Operates reliably from -35°C to +75°C with a metal housing and wide 5-35V DC input. It withstands the vibrations and heat found in electrical cabinets near running gensets.

- Reliable Connectivity: Supports LTE CAT 4/6 and Wi-Fi for high-speed transmission; 1–2 SIM slots (dual-SIM failover), dual-module for load balancing, WWAN/WAN failover; optional GPS for positioning.

- Rich Interface: Equipped with 1x RS232, 1x RS485, 2x DI (status alarm with configurable SMS), 2x DO (relay to turn on/off your field devices), and 5x RJ45 for direct connection to controllers, sensors, and network devices.

- Industrial Protocols: Native support for Modbus TCP/RTU, MQTT and other industrial protocols allows for seamless integration with existing genset controllers and sensors without costly hardware changes.

- Secure & Scalable: Built on OpenWRT Linux OS. It supports secure VPN tunnels (IPsec/OpenVPN) and allows custom development in Python/C/C++, enabling AI integration, unique protocol adaptation, and scalable system evolution.

Solution Integration & Application

1. Perception Layer: Device & Sensor Integration

- Genset Performance Monitoring: The RS485 port (using Modbus RTU) connects to the generator controller, capturing real-time operational data—voltage, current, frequency, run hours, coolant temperature, and fault alarms.

- Fuel & Asset Security Monitoring: Digital Inputs (DI) connect to sensors such as fuel level gauges and cabinet door contacts, providing continuous data on fuel inventory and instant intrusion alerts.

- Remote Command Execution: A Relay Output (DO) wired to the genset’s start/stop circuit enables remote initiation of test runs or backup power activation directly from the cloud dashboard.

2. Network Layer: Secure, Reliable Data Flow

- Data Conversion & Transmission: TG451 converts field device Modbus RTU data to Modbus TCP, then aggregates, normalizes, and securely transmits all sensor/status data.

- Reliability & Security: Data is transmitted via high-speed 4G LTE (CAT 4/6) with Dual-SIM failover, and VPN encryption guarantee end-to-end data integrity for Genset IoT Monitoring.

- Platform Centralization: All data is securely delivered to a central cloud platform, which aggregates information from multiple sites for a unified operational view.

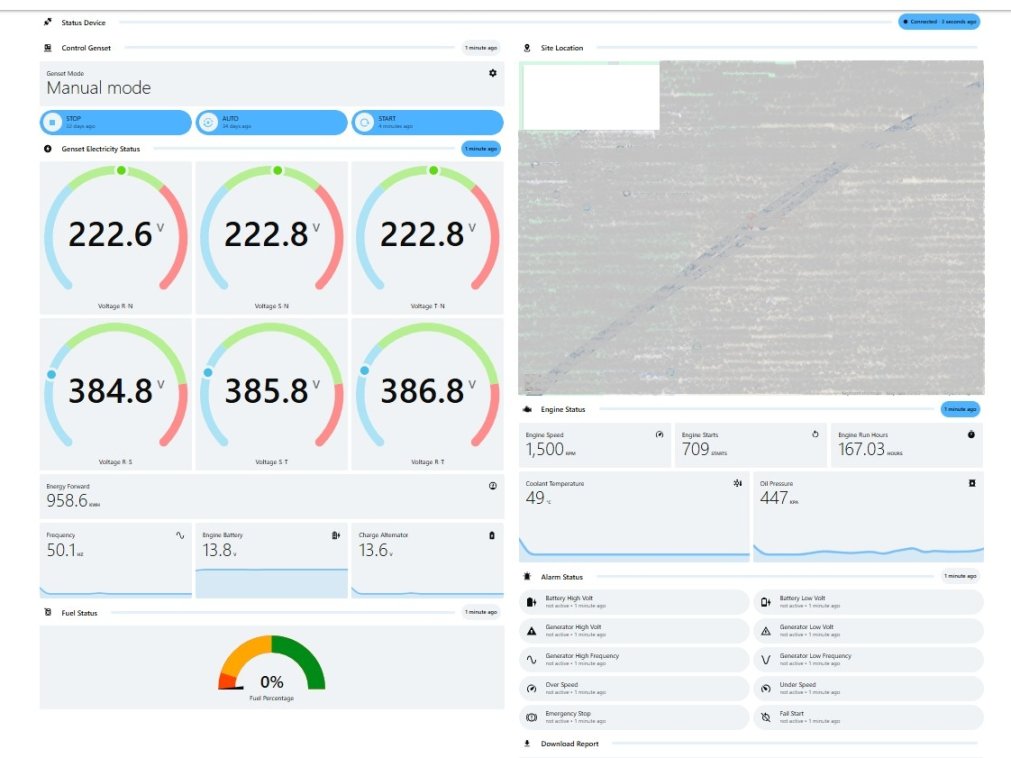

3. Application Layer: Proactive Operations

- Unified Dashboard Visibility: Operators access a single pane of glass for real-time status, fuel levels, and maintenance alerts across all deployed gensets.

- Remote Control & Automated Alerts: Facilitates remote start/stop commands and receives automated alerts (e.g., for low fuel levels) to prevent unexpected downtime.

- Proactive Maintenance & Response: Enables maintenance scheduling based on actual run hours and allows for rapid remote intervention, significantly reducing on-site service response times.

Beyond Toll Roads: Replication & Scalability

The success of this project demonstrates the versatility of Genset IoT Monitoring with Bivocom’s TG451. The solution is equally effective for:

- Remote water pump stations

- Off-grid telecom base stations

- Highway tunnel emergency power systems

- Site power backups

About Bivocom

Bivocom delivers mission-critical Industrial IoT connectivity for critical infrastructure operators. Our Genset IoT Monitoring solutions transform isolated toll road sites into interconnected, data-driven nodes, enabling predictive insights, enhanced reliability, and significantly lower total cost of ownership.

- Scenario Tailored: Customized Genset IoT Monitoring for toll roads, with flexible integration for diverse field devices and legacy systems.

- Operational Certainty: Replaces guesswork and manual checks with always-on, real-time visibility for Genset IoT Monitoring, ensuring backup power is ready when needed.

- Customer Centric: Plug-and-play deployment, global technical support, and scalable upgrades to maximize ROI and minimize downtime.

Ready to Transform Your Genset Fleet?

Bivocom’s Smart Solution for IoT Monitoring is proven to cut costs, boost reliability, and streamline operations. Contact [email protected] for a free customized assessment. Build a smarter, more resilient toll road network today.

Comment