Railway Crossing IoT Monitoring

Bivocom Industrial IoT delivers next-generation monitoring for critical railway infrastructure. Operators worldwide face consistent challenges at unattended railway crossings and remote radio rooms. These include safety blind spots, connectivity issues, and costly manual maintenance. Our compact, high-performance 5G Router TR323, directly addresses these gaps. Deployed by a major Southeast Asian railway operator, the TR323 acts as a central data hub. It integrates sensors, cameras, and control systems. This Railway Crossing IoT Monitoring solution enhances safety compliance and enables predictive maintenance. It also ensures always-on connectivity, transforming operational efficiency and reliability.

Key Pain Points of Distributed Sites

Across Southeast Asia, railway expansion has intensified the need to monitor remote infrastructure. This includes unattended railway crossings and their adjacent radio rooms. Yet their dispersed nature creates persistent challenges. Reliance on manual, scheduled inspections is no longer sustainable. This approach leads to delayed fault detection and inefficient resource use. It ultimately compromises safety and operational uptime. Key Pain Points:

- Safety Blind Spots: No real-time visibility into crossings risks collisions, with issues found only post-incident.

- Connectivity Gaps: Weak cellular signals in remote areas disrupt critical data flow.

- Power & Equipment Risks: Unstable grid power damages equipment, shortens lifespan, and raises operational costs.

- Limited Operational Visibility: Insufficient insight into critical assets (gate relays, batteries, power, IP cameras) requires frequent on-site checks.

- Inefficient Maintenance: Routine site visits delay fault detection, and lead to reactive management.

The overarching goal is clear. It aims to achieve unified, 24/7 visibility into edge infrastructure performance without high cost increases. By spotting early warning signs—like power anomalies or equipment stress—operators shift from reactive responses to predictive maintenance. This ensures safer, more reliable, and cost-efficient railway operations, supported by robust Railway Crossing IoT Monitoring capabilities.

Bivocom Smart Site Solution

To resolve the critical pain points of unattended railway crossings and remote radio rooms, Bivocom’s Smart Site Solution centers on the TR323. That not only bridges gaps in existing systems but also enables full operational visibility, reliable connectivity, and data-driven decision-making. The solution supports plug-and-play deployment, avoiding costly custom integrations. The versatile TR323 consolidates data from diverse field devices. It ensures uninterrupted communication and provides real-time insights. This enables a shift from reactive troubleshooting to proactive management. More than just a connectivity tool, it serves as a strategic enabler.

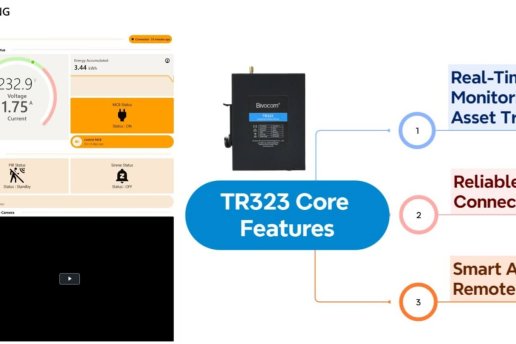

Core Product: TR323 Industrial Mini 5G Router

- Industrial Durability: Operates from -35°C to +75°C with IP30 protection and 15KV ESD shielding. Its compact DIN-rail mountable design (103.5×78.2×24.1mm) fits space-constrained cabinets. A 5–35V DC wide-voltage input ensures compatibility with unstable grids and backup batteries.

- Uninterrupted Connectivity: Features dual SIM slots with automatic failover. This provides reliable data transmission even in remote, low-signal areas.

- High-Performance Data Hub: A powerful 32-bit dual-core CPU and 256MB RAM handle concurrent data streams from multiple IP cameras and sensors with low latency. This enables real-time visibility and responsive control.

- Multi-Device Compatibility: Equipped with 2 Gigabit Ethernet and 2 RS485 serial ports. It natively connects a wide array of field equipment and supports protocols like Modbus and MQTT.

- Secure & Scalable Software: Built on OpenWRT Linux OS. It supports secure VPN tunnels (IPsec/OpenVPN) and allows custom development in Python/C/C++, enabling AI integration, unique protocol adaptation, and scalable system evolution.

Solution Integration & Application

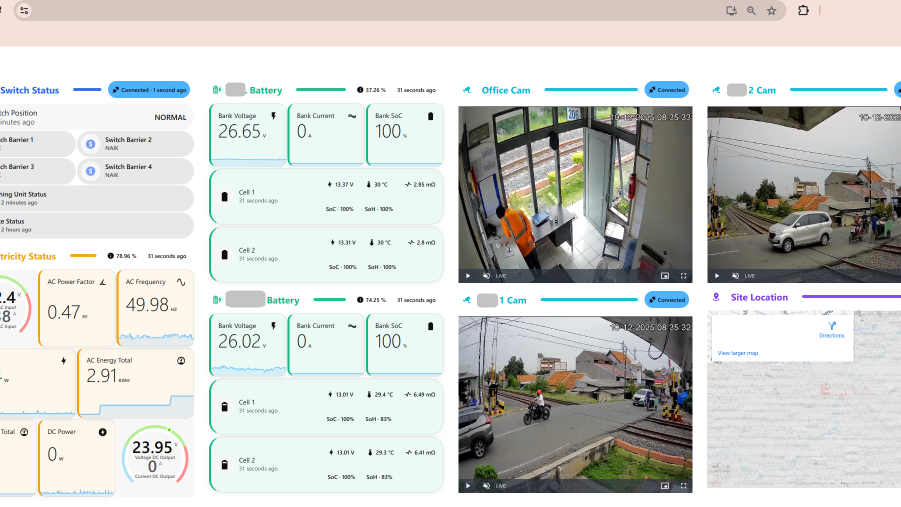

- Power System Monitoring: Dual RS485 ports connect to smart power meters and dual-battery sensors. They capture grid voltage, frequency, power factor, and battery health metrics (voltage, temperature, SOC, SOH).

- Equipment Status Monitoring: RS485 interfaces integrate signals from 4 barrier position sensors, warning lights, and brake systems. It delivers real-time barrier and equipment status to reflect on-site conditions.

- Security & Data Flow: IP cameras connect via Gigabit Ethernet for live video. An optional GNSS module adds precise site location. The router collates all sensor and video data, normalizes it via Modbus/MQTT, and transmits it securely to the cloud via 5G/4G with VPN encryption.

- System Protection Feedback: It communicates with circuit breakers and surge protectors. Operational status is fed back to the cloud platform. This aligns with the site’s electrical protection setup.

This integrated Railway Crossing IoT Monitoring solution turns data into actionable insights. It delivers concrete operational advantages. It shifts safety management from reactive to proactive. Early equipment fault detection becomes possible. Continuous remote monitoring cuts down manual site inspections significantly. It optimizes maintenance schedules and resource allocation. Together, these capabilities enhance safety compliance, improve asset uptime, and lower the total cost of ownership for distributed critical infrastructure.

Scalability & Replication

The solution’s architecture is inherently scalable and replicable. The same TR323-based Railway Crossing IoT Monitoring model can be deployed across hundreds of unattended sites. These include railway crossings, remote signaling cabinets, and communication repeater stations. A centralized cloud platform manages a vast fleet of gateways. It provides a unified view of the entire network’s health. This makes it an ideal framework for regional or national infrastructure modernization programs.

Future-Ready Upgrade

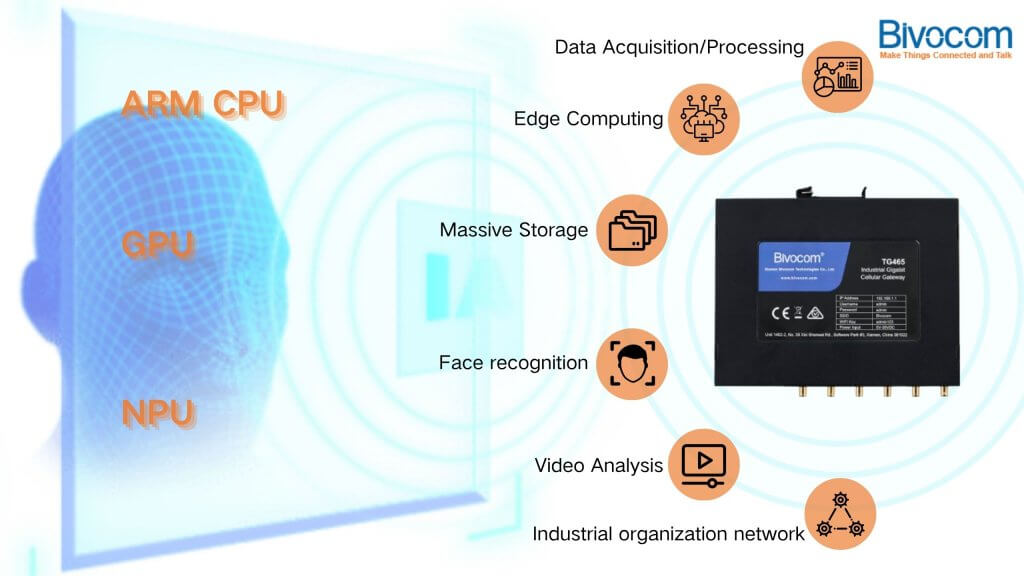

As railway operations evolve toward autonomy and AI-driven decision-making, the solution can upgrade seamlessly to Bivocom TG465 Programmable 5G Edge Gateway. It is designed for complex railway IoT ecosystems. The TG465 retains the TR323’s reliability while adding advanced capabilities to future-proof operations:

- Enhanced Processing Power: A high-performance CPU supports Ubuntu/Docker containers. It enables edge computing for video AI analytics (e.g., vehicle/pedestrian detection) and fault pattern recognition. This reduces cloud bandwidth costs and latency.

- Expanded Interface Capacity: 6 RS485 ports support industrial protocols like OPC UA and IEC 104. It integrates diverse sensors and legacy systems, ideal for large-scale railway networks.

- Precision Integration: Pair with Bivocom TN531 High-Precision GNSS Receiver (centimeter-level positioning). It monitors track/bridge deformation and enables precise train scheduling. This is critical for autonomous train operations (ATO).

For operators scaling beyond basic monitoring to predictive intelligence, the TG465 offers a seamless upgrade path. It is fully compatible with existing Railway Crossing IoT Monitoring components while unlocking advanced use cases.

About Bivocom

Bivocom delivers mission-critical Industrial IoT connectivity. We bridge safety and operational gaps in unattended railway environments. Our Railway IoT solutions transform isolated sites into interconnected, data-driven nodes, enabling predictive insights, enhanced safety, and significantly lower total cost of ownership.

- Scenario-Tailored Design: Customized Railway Crossing IoT Monitoring for diverse rail scenarios. It scales cross-industry for critical infrastructure needs.

- Operational Certainty: Replaces guesswork and manual checks with always-on, real-time visibility. It enables data-driven decisions to prevent failures and boost safety.

- Engineered Resilience: Our hardware is built for extreme conditions. It ensures uninterrupted operation despite temperature swings, power instability, and remote locations.

- Customer-Centric Agility: Plug-and-play deployment, legacy system integration, and 24/7 global technical support minimize downtime and maximize ROI.

Bivocom IoT solutions boost safety, efficiency, and scalability for critical rail assets. Contact [email protected] for a free customized assessment. Build a smarter, more resilient rail network today.

![[Case Study] Bivocom Smart Pole TG451 & Sensors](https://www.bivocom.com/wp-content/uploads/2026/09/Case-Study-Bivocom-Smart-Pole-TG451-Sensors-768x512.png)

Comment