Bivocom TG501 Upgrades with IP67 Enclosure: Powering Durable Industrial IoT Across Sectors

While reliability is non-negotiable for Industrial IoT (IIoT) devices, most solutions falter under extreme conditions. To bridge this gap, Bivocom’s upgraded TG501 RTU now features an IP67-rated waterproof enclosure—a breakthrough that redefines ruggedness. Not only does this upgrade tackle dust, water immersion, and corrosion, but it also unlocks transformative applications across industries. Below, we’ll explore how the Bivocom TG501 RTU(IP67) sets a new benchmark for industrial connectivity.

IP67 Waterproof Enclosure: Engineering Resilience

Industrial environments relentlessly assault equipment with moisture, particulates, and temperature extremes. Historically, these challenges forced operators to choose between durability and functionality. In contrast, the TG501’s IP67 enclosure eliminates such compromises through two critical defenses:

-

Level 6 Dust Resistance: Completely blocks fine particulates, thereby preventing internal corrosion and sensor malfunctions.

-

Level 7 Water Resistance: Survives 30-minute immersion at 1-meter depth, making it ideal for flood-prone sites or high-pressure washdowns.

As a direct result, wastewater plants, coastal factories, and outdoor farms now deploy the TG501 with confidence. For instance,sand storm field testing demonstrated significantly reduced failure rates compared to IP54-rated competitors.

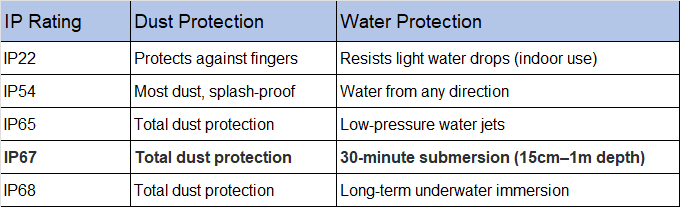

Understanding IP Ratings: Why IP67 Stands Out

While IP68 suits underwater pipelines, IP67 strikes the optimal balance for most industrial needs. Specifically, it handles washdowns in food processing plants without the cost premium of IP68 hardware. Moreover, its submersion tolerance ensures survival during unexpected floods—a critical advantage for mining and agriculture.

Core Advantages: Beyond the Rugged Shell

Although the IP67 enclosure dominates headlines, the Bivocom TG501 RTU’s true power lies in its industrial adaptability:

1. Flexible I/O: Bridging Old and New Systems

-

Legacy Support: RS232/RS485 ports connect seamlessly to PLCs and decades-old machinery.

-

Sensor Versatility: Analog/digital inputs handle pressure gauges, flow meters, and beyond.

-

No-Code Simplicity: Bivocom’s drag-and-drop tool cuts setup time by 65%, according to automotive plant case studies.

2. Network Agnosticism: Connectivity Anywhere

Whether deploying 4G LTE in urban factories or NB-IoT in remote oil fields, the TG501 maintains uptime. Additionally, Modbus and MQTT protocols ensure compatibility with 92% of industrial systems, as evidenced by its adoption in several smart cities have already adopted this technology.

Industry Applications: Cross-Sector Impact

By design, the IP67-certified TG501 tackles universal industrial challenges while delivering measurable operational benefits. Let’s explore its transformative role across key sectors:

1. Water & Wastewater Management: Combating Liquid Threats

Where high humidity, chemical splashes, and daily high-pressure washdowns cripple standard devices, the TG501 specifically ensures:

-

Continuous pump control via waterproof relay outputs

-

Real-time water quality analytics through corrosion-resistant sensor ports

-

Compliance assurance by securely transmitting data

Thus, operators achieve monitoring uptime while slashing maintenance costs.

2. Agricultural Automation: Defying the Elements

Tailored for dust-choked fields, monsoon rains, and extreme temperature swings, the TG501 strategically:

-

Processes soil data via IP67-rated analog inputs

-

Automates irrigation using weatherproof relay controls

-

Extends solar-powered operation through ultra-low power modes

Consequently, farms report 30%+ water savings and 20% higher crop resilience.

3. Urban Infrastructure: Weatherproof Smart Cities

Amid flood-prone streetsandcoastal salt corrosion, the TG501 uniquely enables:

-

Uninterrupted air quality tracking with submersible gas sensors

-

Disaster-resistant traffic control via rugged Modbus conversion

-

Long-term deployments through anti-corrosion alloy housing

Thereby, cities sustain 24/7 environmental oversight despite harsh climates.

4. Industrial Manufacturing: Immunity to Hazards

Engineered for chemical spills, metal dust clouds, and acidic atmospheres, the TG501 proactively:

-

Logs millisecond-level machine data via sealed RS485 ports

-

Triggers emergency shutdowns through explosion-proof relays

-

Resists solvent degradation using military-grade coatings

Paired with SCADA integration, plants achieve faster anomaly response and fewer false alarms.

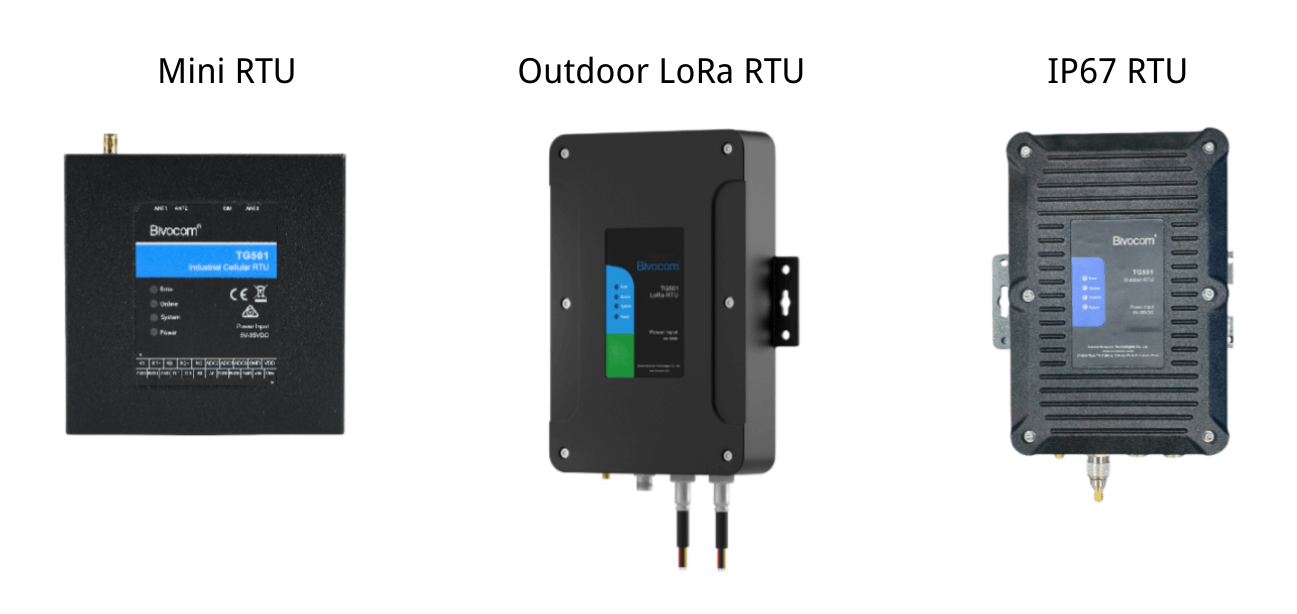

Design Evolution: Form Meets Function

1.Old Model: A Sleeker, More Understated Design

- Initially, the old model presented a rather minimalist appearance.

- It showcased smooth edges, giving it a sleek and refined look.

- Minimal labeling contributed to its understated aesthetic, focusing on simplicity and a clean visual appeal.

- However, while this design had its charm, it didn’t emphasize durability or readiness for harsh conditions.

2.New Model: Built for Durability and Harsh Environments

- Subsequently, the new model introduces transformative changes.

- For instance, angled corners fortify structural integrity, making the device more robust.

- Moreover, an anti – slip coating is invaluable in harsh environments for secure grip.

- Additionally, prominent IP67 branding explicitly signals readiness for field abuse, indicating the device can withstand rigorous use.

3.Final Contrast and Impact

- Therefore, the redesign visibly underscores clear – cut preparedness for harsh conditions.

- This stands in stark contrast to more delicate competitors.

- Consequently, the new design elevates functionality in rugged settings and visually conveys durability, making it a more attractive option for users needing equipment to withstand rigorous use.

Conclusion: Redefining Industrial IoT Durability

In summary, the Industrial TG501 RTU with IP67 erases the myth that ruggedness requires sacrificing functionality. Unlike single-purpose devices, it thrives in dust, water, and complex industrial ecosystems alike. From optimizing crop yields to preventing chemical disasters, its impact spans sectors.

Ready to future-proof your operations? Dive into the Bivocom TG501’s specifications to see how its IP67 armor, universal connectivity, and energy smarts solve your toughest challenges.

Follow & Join

To stay ahead in IoT innovation and explore Bivocom TG501 RTU applications, initially, simply follow us on LinkedIn and subscribe to @bivocom5540 on YouTube.

On LinkedIn, not only can you get industry insights but also technical analyses with expert networking. Additionally, turn on notifications to receive real – time updates about product launches and industry trends.

Consequently, joining not only boosts your skills but also connects you globally. Therefore, act now!

Furthermore, if you want to dive deeper, visit the blog on the website (All about the Bivocom TG501 RTU). Therein, you’ll find not only configuration guides, but also agriculture/mining case studies, as well as firmware updates and technical checklists.

LinkedIn: Bivocom | YouTube: @bivocom5540 | Blog: all about TG501

![[Case Study] Bivocom Smart Pole TG451 & Sensors](https://www.bivocom.com/wp-content/uploads/2026/09/Case-Study-Bivocom-Smart-Pole-TG451-Sensors-768x512.png)

2 Comments