Industrial Boiler Remote Monitoring and Alarm Systems Enhancing Efficiency and Safety

In the realm of industrial processes, boilers play a crucial role in various applications, such as power generation, heating, and steam production. Ensuring the smooth operation of these boilers is vital for both efficiency and safety within industrial facilities. This is where remote monitoring and alarm systems are revolutionizing how boiler systems are managed and maintained.

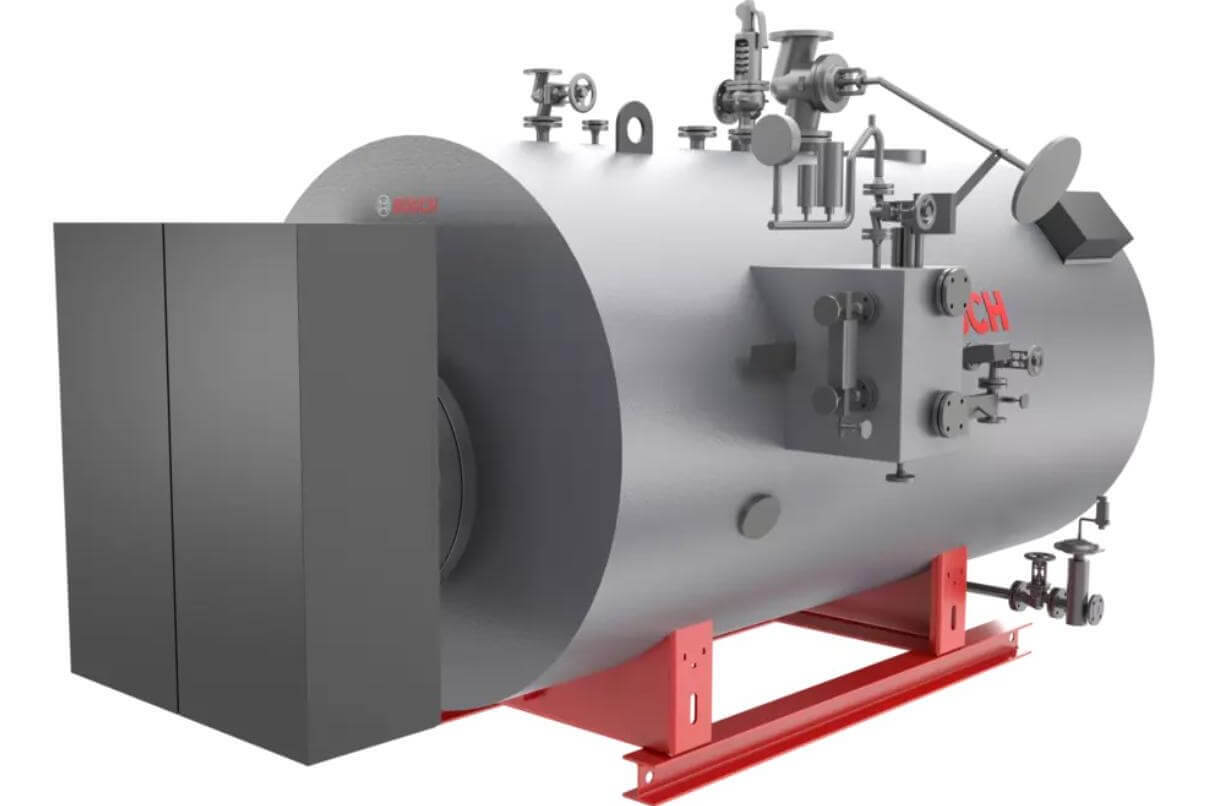

What is an Industrial boiler?

An industrial boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, such as powering machinery, heating buildings, or producing steam for various industrial purposes.

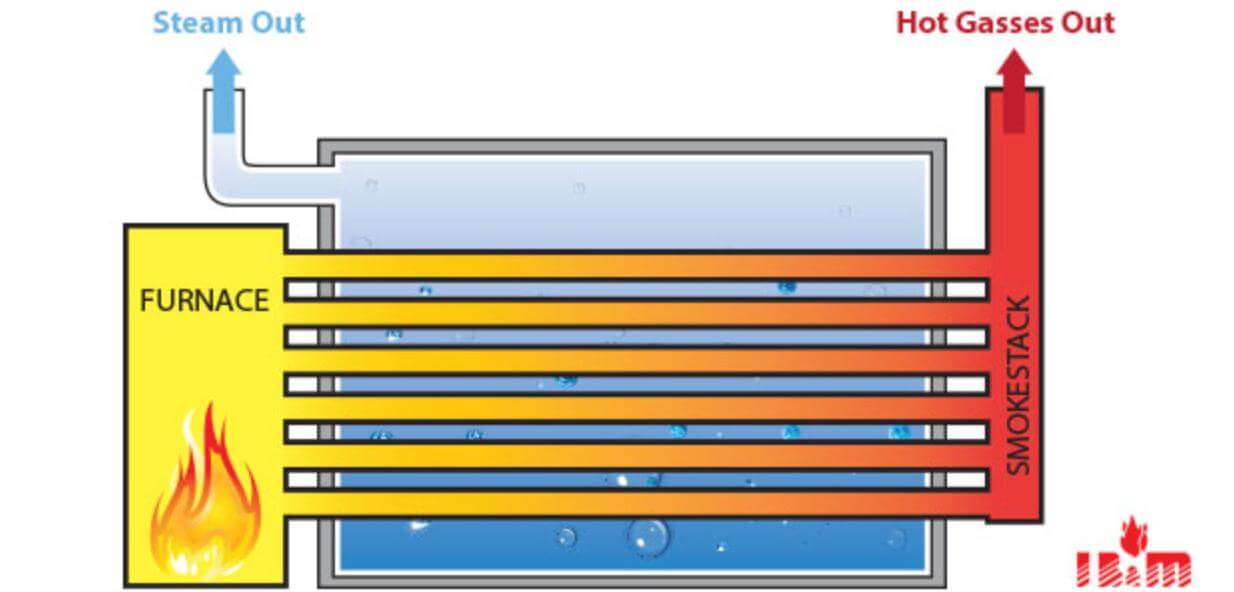

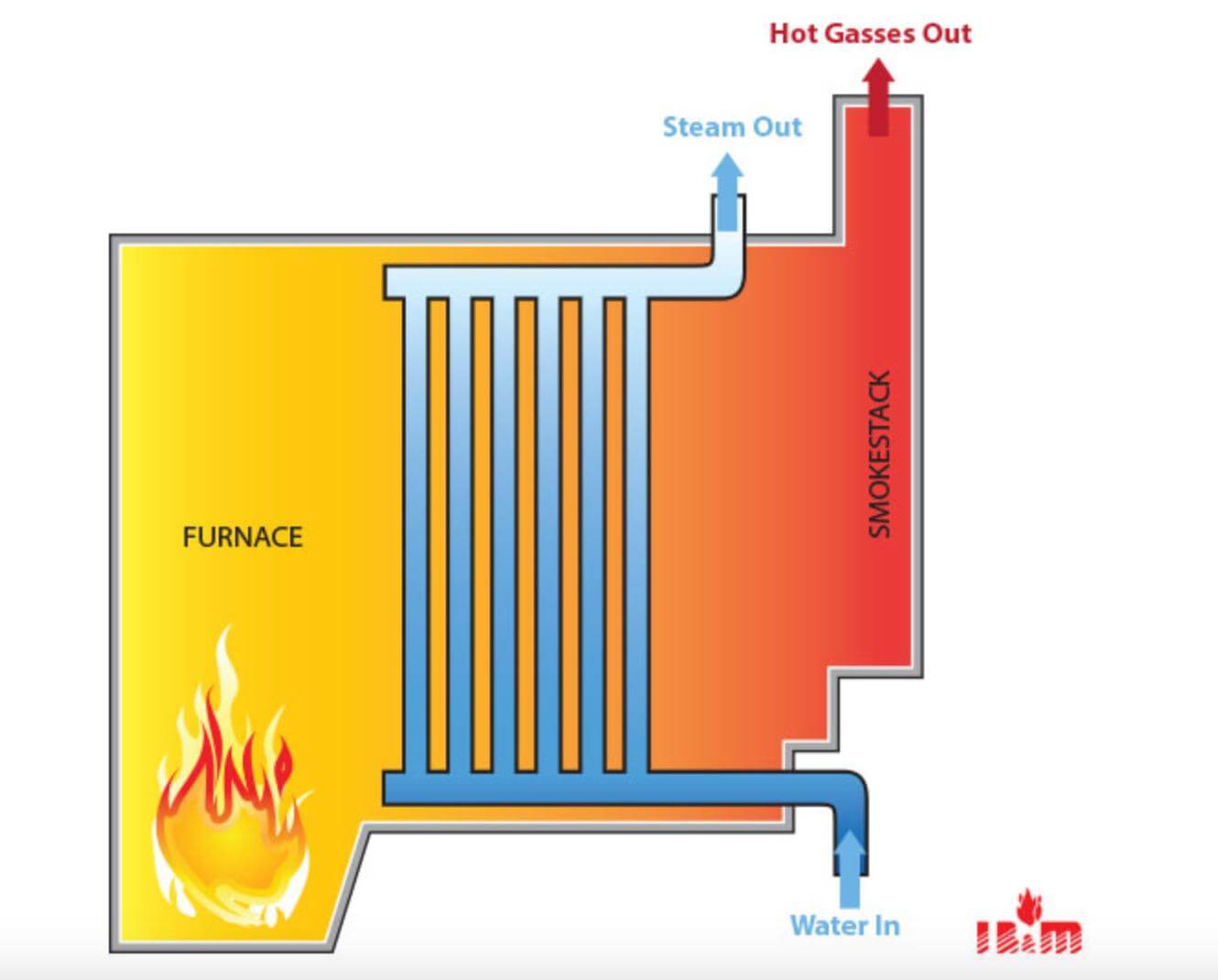

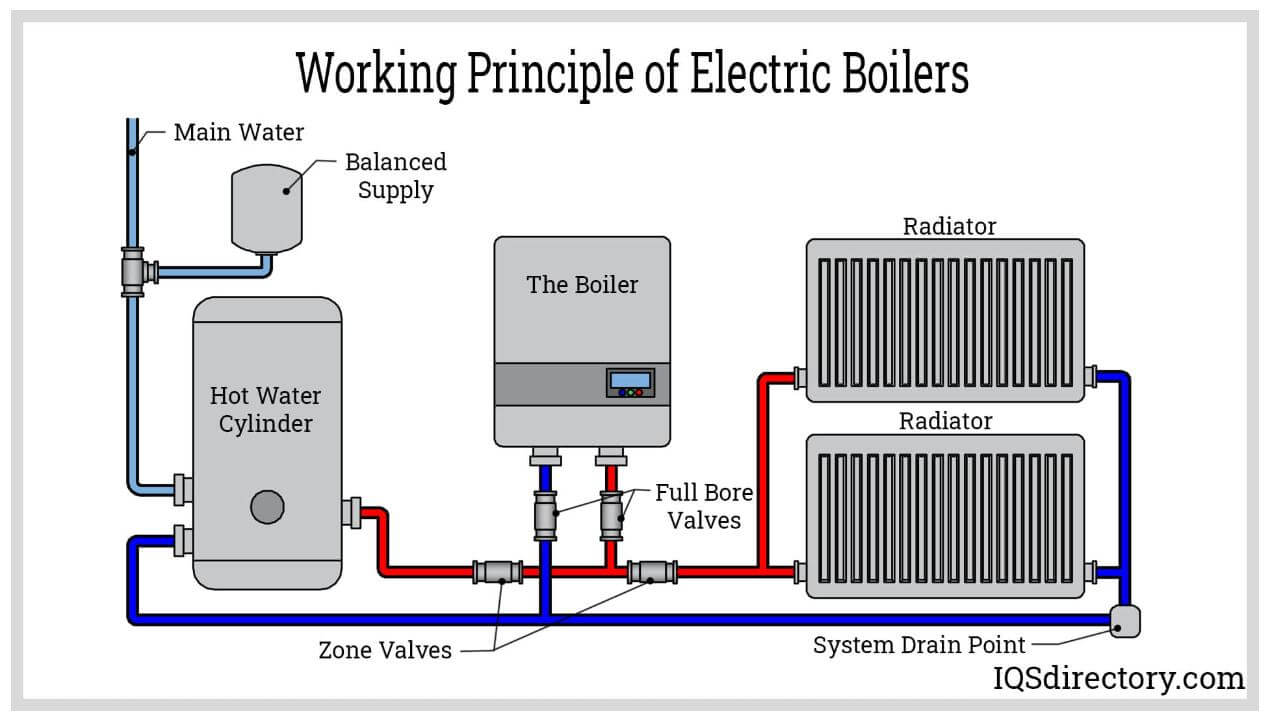

Industrial boilers come in various configurations and designs, such as fire-tube boilers, water-tube boilers, and electric boilers, and they are commonly used in industries like power generation, manufacturing, chemical processing, and more. These boilers play a crucial role in many industrial processes where heat or steam is required for operations.

Industrial boiler

Image source: https://www.bosch-industrial.com/global/en/ocs/commercial-industrial/electric-steam-boiler-elsb-19175285-p/

Fire tube boiler

image source: https://industrialboiler.com/boilers/firetube-boilers

Water tube boiler

Image source: https://industrialboiler.com/boilers/watertube-boilers

Electric boiler

Image: https://www.industrial-boilers.com/electric-boilers/

The Need for Remote Monitoring and Alarm Systems

Industrial boilers are complex systems that require regular oversight to prevent potential malfunctions, downtime, or safety hazards. Traditionally, on-site personnel have been responsible for monitoring and troubleshooting these systems. However, this approach can be labour-intensive, time-consuming, and prone to human error.

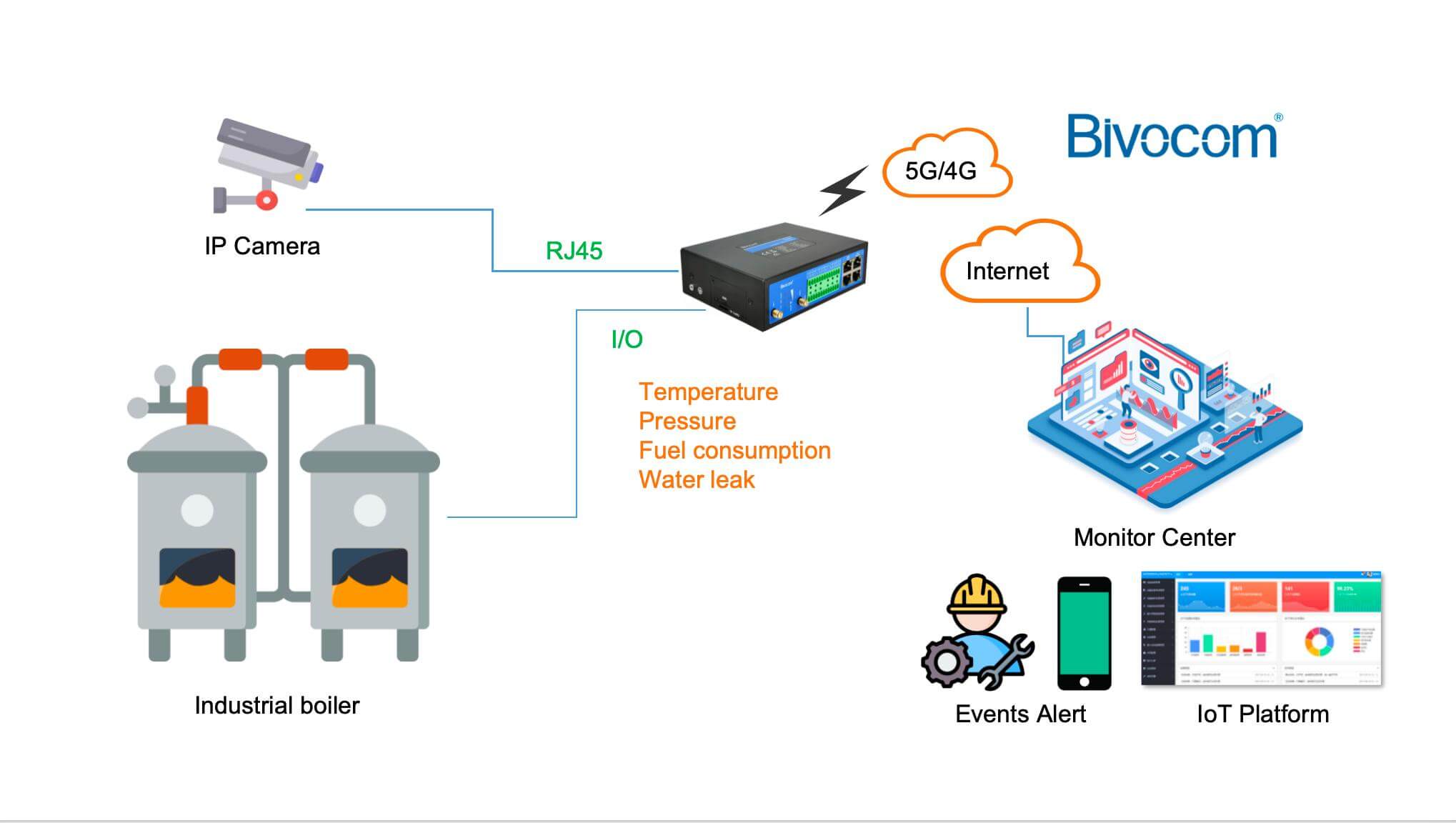

Remote monitoring and alarm systems offer a solution by providing real-time visibility into the performance and condition of industrial boilers from a remote location. By leveraging sensors, data analytics, and connectivity technologies, these systems enable operators to monitor key parameters, detect anomalies, and respond promptly to alarms without being physically present on-site.

Key Features and Benefits

Real-time Data Monitoring: Remote systems continuously collect and transmit data on boiler performance metrics, such as temperature, pressure, and fuel consumption, allowing operators to make informed decisions based on real-time information.

Predictive Maintenance: By analyzing data trends and patterns, remote monitoring systems can predict potential equipment failures or maintenance needs before they occur, enabling proactive maintenance and minimizing unplanned downtime.

Alarm Notifications: Instant alerts and notifications are triggered in the event of abnormalities, deviations from set parameters, or critical malfunctions, ensuring timely intervention and preventing catastrophic incidents.

Remote Control: Some advanced systems allow operators to remotely adjust settings, initiate shutdown procedures, or troubleshoot minor issues without needing physical presence, thereby increasing operational efficiency.

Historical Data Analysis: The ability to store and analyze historical data facilitates performance tracking, trend analysis, and optimization of boiler operations over time, leading to improved efficiency and cost savings.

Implementation and Integration

Integrating remote monitoring and alarm systems into existing industrial boiler infrastructure involves deploying sensors and communication devices, setting up a secure network for data transmission, and configuring a centralized monitoring platform. Collaboration with experienced technology providers and system integrators is essential to ensure seamless implementation and integration with minimal disruption to operations.

Future Trends and Innovations

As digitalization and Industry 4.0 initiatives continue to drive technological advancements in industrial automation, the future of boiler monitoring is poised for further innovation. Artificial intelligence, machine learning, and Internet of Things (IoT) applications are expected to enhance the capabilities of remote monitoring systems, enabling autonomous operation, adaptive control strategies, and predictive analytics for optimal boiler performance.

Conclusion

Industrial boiler remote monitoring and alarm systems represent a paradigm shift in the way boiler operations are managed, offering enhanced efficiency, safety, and reliability. By leveraging data and connectivity, these systems empower industrial facilities to operate their boiler systems with greater precision, responsiveness, and intelligence, ultimately driving productivity and sustainability in the industrial landscape.

![[Case Study] Bivocom Smart Pole TG451 & Sensors](https://www.bivocom.com/wp-content/uploads/2026/09/Case-Study-Bivocom-Smart-Pole-TG451-Sensors-768x512.png)

Comment