Smart Pumping: Solving Water Crises with Connected Tech

How Bivocom Powers Smart Pump Stations

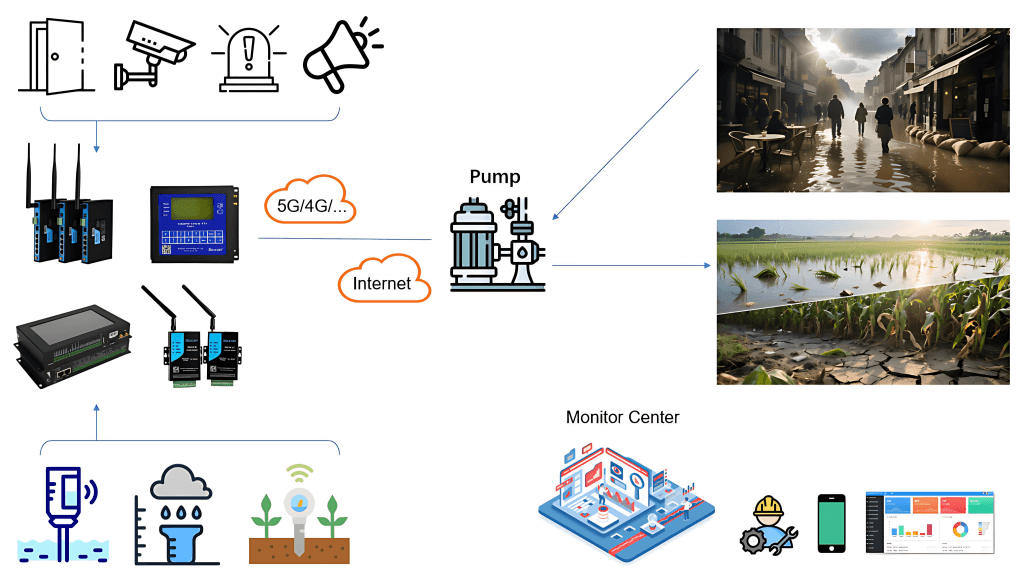

1. Real-Time Data Acquisition: Proactive Monitoring for Critical Scenarios

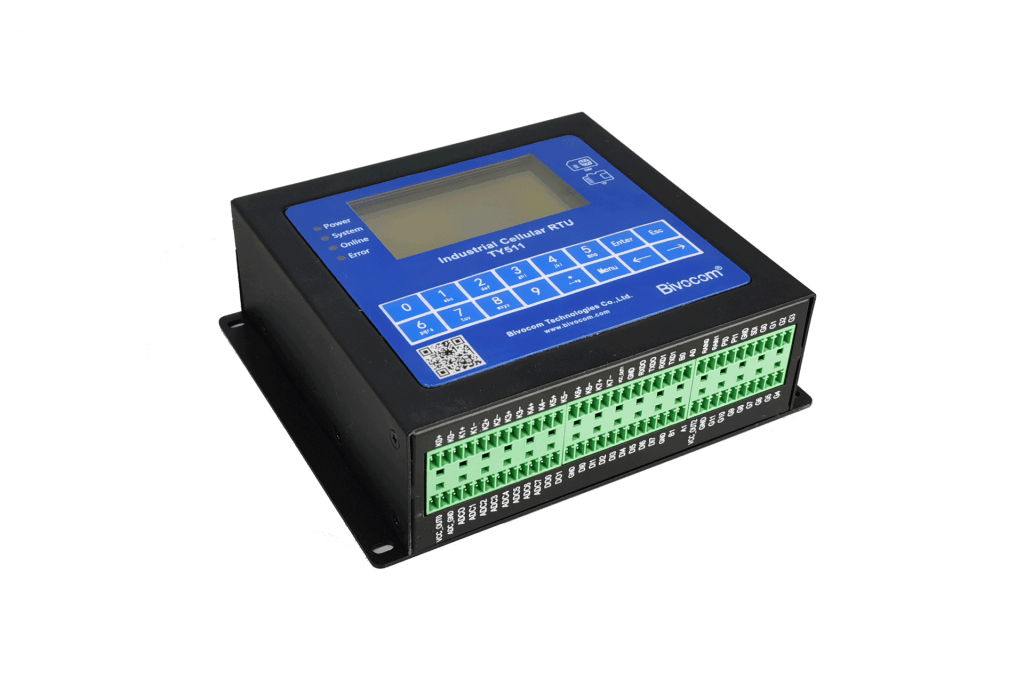

TY511 LCD RTU serves as the data backbone, primarily because of its:

- Multiple interfaces: Specifically, 8 ADC channels and 8 DI ports, it not only accurately gathers data from water level sensors, rain gauges, and soil moisture probes but also monitors equipment status in real time. This includes, for instance, door positions, CCTV feeds, and warning lamp activation.

- In flood control, it logs water height spikes in its 16MB local storage, whereas in irrigation, it tracks pump workload to prevent overuse.

- Additionally, configurable thresholds (e.g., water level >1.2m) activate SMS alerts via 4G LTE CAT 4, thereby enabling timely responses.

TD210 IoT Cellular Modem ensures data reliability, especially in remote areas. For instance, its global 4G/3G/2G support maintains connectivity, and the 5-sync data center feature backs up irrigation data—critical for preventing loss during flood emergencies.

2. Intelligent Remote Control: Adaptive Automation at Scale

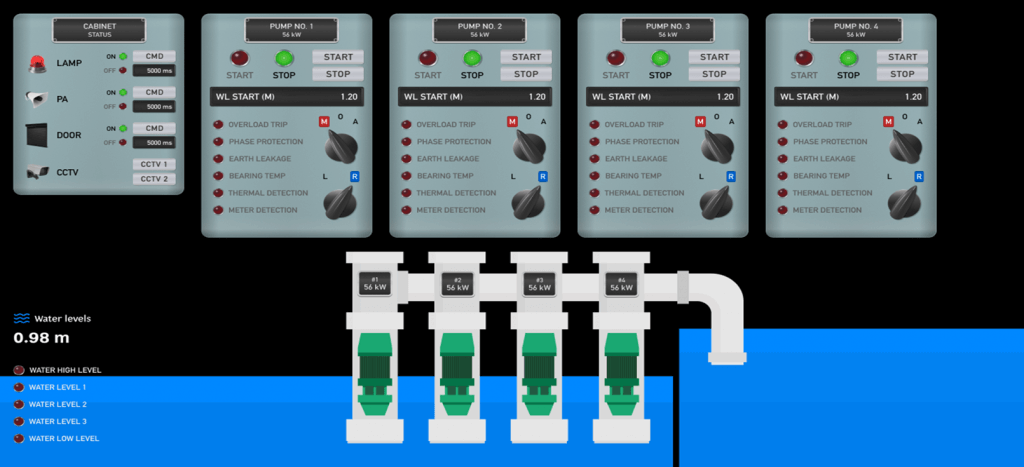

TG462S Touch Screen Gateway acts as the system’s brain, notably with:

- Custom Logic Programming: Operators use Python or Node-RED to set rules like “Start Pump 1 during 50mm/h rainfall” (flood control) or “Halt irrigation at 60% soil moisture” (water conservation). Correspondingly, the 7″ touch screen visualizes real-time metrics, such as pump status and flow rates, for intuitive management.

TR341 Industrial Router enhances operational resilience. For example, its dual SIM failover maintains connectivity during floods, while VPN encryption secures irrigation data. Furthermore, GPS tracking optimizes mobile pump deployment for large farms.

3. Fault Protection: Prevent Breakdowns Proactively

All devices share industrial-grade durability, such as:

- Wide Temperature Resistance: -35°C to +75°C operation ensures year-round functionality in extreme climates.

- Redundancy Features: The TY511’s hardware watchdog and TR341’s WAN failover prevent crashes during severe weather, while the TG462S logs errors for predictive maintenance. Consequently, this reduces unexpected downtime by 50%.

- Overload (150%+ workload spikes)

- Phase loss (electrical supply anomalies)

- Earth leakage (safety hazards within 100ms)

- Bearing temperature (>80°C alerts)

- Water level (real-time tracking for flood prevention)

- Lamp/PA activation (alarm systems)

- Door/CCTV monitoring (security for pump stations)

Real-World Impact: Flood&Irrigation Pump Case Study

Bivocom’s Diverse Water Industry Applications

1. Water Quality Assurance and Pollution Control

In industrial park management, Bivocom’s Environment Monitoring Solution for Chemical Industry Park plays a pivotal role. For instance, our products connect to an array of sensors—including pH, COD, ammonia nitrogen, and conductivity probes—that continuously monitor water and air quality parameters. If the readings exceed regulatory thresholds, the system, accordingly, automatically triggers alarms and shuts off valves to initiate emergency treatment procedures. This proactive approach not only effectively reduces pollution risks but also significantly supports industries in their green transformation efforts.

Bivocom’s solution: Environment Monitoring Solution for Chemical Industry Park

2. Water Resource Optimization and Reuse

In an era of escalating water scarcity, Bivocom’s Municipal Wastewater Reuse for Agricultural Irrigation System stands as a prime example of our innovation. As a matter of fact, this solution employs a IoT gateway to closely monitor the quality of treated municipal wastewater. Once the water meets the required agricultural standards, it is, then, automatically diverted for irrigation purposes. In doing so, this approach effectively alleviates the pressure on freshwater resources while simultaneously maximizing the overall efficiency of water usage. In addition, this approach has been proven to reduce agricultural water waste by up to 30%, clearly demonstrating how IoT can transform waste into a valuable resource.

Bivocom’s case study: Municipal Wastewater Reuse for Agricultural Irrigation System

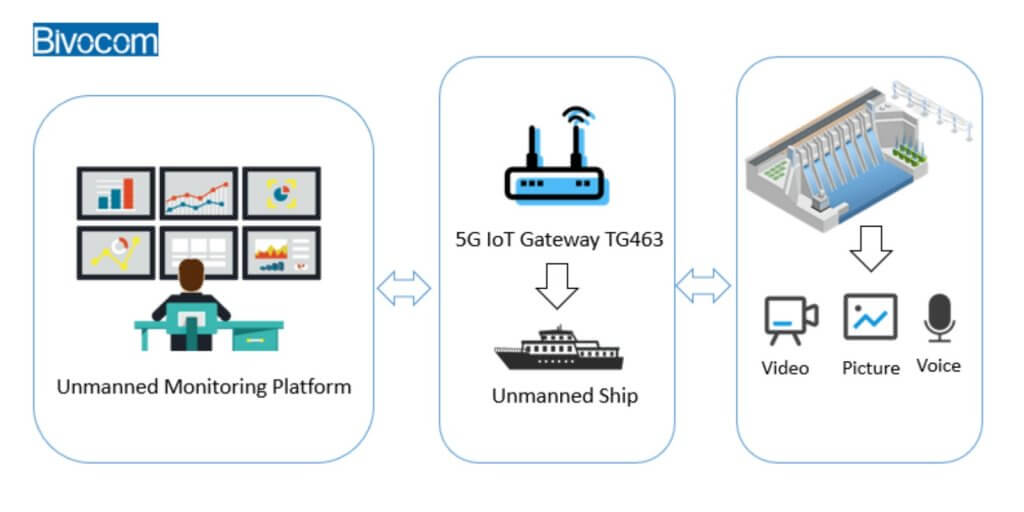

3. Infrastructure Inspection and Maintenance

Turning to water project infrastructure, Bivocom’s automated underwater structure inspection system leverages cutting-edge technology. Specifically, the solution utilizes TG463 5G IoT gateways, unmanned vessels, underwater sonar, and high-definition cameras to achieve sub-millimeter accuracyin structural monitoring. Unmanned vessels, equipped with these advanced tools, can reach hard-to-access underwater areas and, subsequently, transmit real-time images and sonar data over 5G networks. Our AI algorithms, then, analyze this data to identify potential structural defects, such as cracks and corrosion. As a result, by replacing dangerous manual diving inspection methods, we enhance both the efficiency and safety of infrastructure maintenance.

Bivocom’s solution: How 5G and IoT Empowers Automatic Inspection of Water Conservancy

Why Choose Bivocom?

- Industrial – Grade Reliability: Our devices withstand extreme temperatures, humidity, and dust—certified for 24/7 industrial use.

- End – to – End Integration: Modems, routers, gateways, RTUs, and our IoT platform work seamlessly together—no compatibility issues.

- Proven at Scale: From small farms to urban flood networks, Bivocom powers projects in 90+ countries. We turn concepts into tangible results.

Conclusion: Bivocom’s Mission for Sustainable Water Futures

Join the Smart Pump Revolution

Given that the demand for efficient water management is growing amidst escalating climate challenges, Bivocom is consequently committed to offering innovative Flood&Irrigation Pump Case Study. To this end, and specifically to help you embrace this technological leap, we have accordingly outlined actionable steps to enhance your water infrastructure.

- Custom Trials: Test our tailored Smart Pump solutions in your environment with low risk, validating performance before full deployment.

- Expert Collaboration: Work with our engineers to design a scalable architecture that fits your unique site needs, whether rural or urban.

- Live Previews: Get hands-on access to our IoT platform’s dashboards and AI controls, seeing real-time insights into pump operations.

Ready to transform your water management?

Contact [email protected] for a demo or personalized plan. By choosing Bivocom, you’re not only upgrading your pumps—you’re paving the way for a more efficient, resilient water future. Let’s build smarter, sustainable pump stations together.

Facebook: Bivocom | YouTube: @bivocom5540

1 Comment