Bivocom’s End-to-End Base Station Monitoring Solutions

Addressing Core Challenges

1. Energy Waste & Inefficiency

2. Thermal Hazards in 5G Systems

Challenge: The high power density of 5G’s Massive MIMO technology often pushes component temperatures beyond 85°C, risking catastrophic failures like fires. as evidenced by the Moss Landing fire. Due to inadequate monitoring and emergency response planning, the Moss Landing battery fire lasted for several days, resulting in significant environmental impacts.

Solution: Advanced sensors continuously track voltage, temperature, and internal resistance of VRLA and lithium batteries. When combined with AI-driven predictive analytics (92% accuracy), these tools identify early signs of thermal runaway.

3. Security Breaches in Remote Sites

Challenge: Remote base stations are prime targets for theft, particularly of copper feeders and batteries, with each incident costing up to $10,000 in downtime and replacements.

Solution: Bivocom integrates PIR (passive infrared sensor) motion sensors, vibration detectors, and IP cameras with IoT gateways to create a unified security ecosystem. Upon detecting unauthorized access, the system triggers strobe alarms and instant notifications.

4. Legacy System Fragmentation

Challenge: Fragmented protocols and outdated hardware in legacy systems create monitoring gaps, leading to delayed fault resolution and high integration costs.

Solution: Bivocom’s edge computing gateways (e.g., TG451) support multi-protocol integration (Modbus, SNMP, MQTT, etc.), unifying data from disparate devices. Through local data preprocessing reduces cloud traffic, enabling sub-second alerts for critical events like power outages or HVAC failures.

Bivocom’s Technology Ecosystem

Bivocom’s integrated hardware-software ecosystem delivers comprehensive base station monitoring solutions. Specifically, our industrial-grade hardware captures critical data, while our AI-driven software transforms it into actionable insights. Consequently, operators achieve unprecedented reliability across diverse environments. Below is a streamlined breakdown:

Industrial-Grade Hardware: Rugged Connectivity for Diverse Scenarios

Key Functionality: Not only seamless legacy integration and real-time data collection,but also extreme-environment resilience.

1. Gateways: The Core of Data Integration

TG451 Industrial IoT Gateway

- Multi-Protocol Support: Modbus/SNMP/MQTT for unified power/HVAC/security data.

- Dual SIM Redundancy: Ensures 99.99% uptime via automatic failover—particularly vital for remote sites.

- Edge Computing: Reduces cloud traffic, enabling sub-second alerts (e.g., battery failures).

- Rugged Design: Operates in -35°C to +75°C with IP30 protection, especially suited for coastal/mountainous zones.

TG452 IoT Edge Gateway

- Enhanced I/O: 2-RS232/3-RS485 supports advanced thermal/vibration sensors.

- Programmable Logic: OpenWRT Linux runs Python/Node-RED for custom analytics (radiation monitoring, for instance).

- Dual Module Load Balance: Optimizes 5G video surveillance, thereby enhancing high-bandwidth applications.

2. Routers: Reliable Connectivity for Mission-Critical Sites

TR323 Industrial Mini 5G IoT Router

- 5G/4G Redundancy: Future-proofs networks with low-latency backhaul and GNSS tracking.

- Compact Rugged Design: DIN-rail mountable and IP30-rated, making it ideal for micro-cells.

TR341 Industrial 5-Port Router

- Multi-Device Connectivity: 5 ports for IP cameras/sensors, consequently streamlining urban macro stations.

- Secure VPN & WiFi: IPsec/PPTP encryption with Radius authentication ensures compliance.

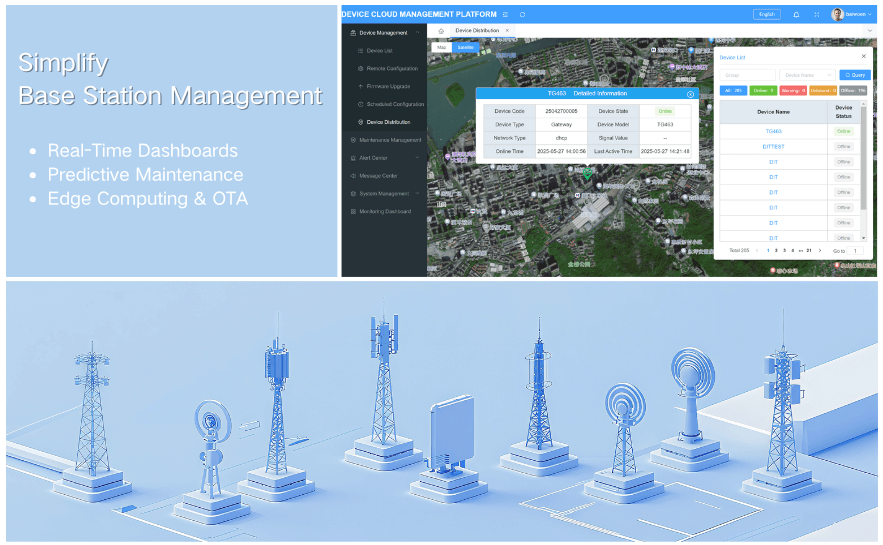

AI-Driven IoT Platform: Transforming Data into Action

Key Functionality: Beyond real-time dashboards to predictive maintenance.

- Real-Time Dashboards: Monitoring energy, EMF (Electromagnetic Field) radiation, and SLA (Service-Level Agreement) compliance, along with automated tenant billing for shared sites.

- Predictive Maintenance: AI forecasts failures (e.g., battery degradation), slashing downtime by 80%.

- Edge Computing & OTA: Local data processing reduces cloud reliance, while remote firmware updates minimize operational disruptions.

Global Impact: Scalable Solutions

Why Choose Bivocom?

Base station monitoring is strategic—and Bivocom delivers unmatched value through three pillars:

Cost Efficiency: Dynamic power management actively cuts energy waste by 15–20%, thereby optimizing operational budgets. Meanwhile, AI-driven predictive maintenance leverages machine learning to reduce unplanned downtime by 80%, ensuring continuous network reliability. These combined measures not only address immediate cost concerns but also lay the foundation for long-term savings.

Risk Reduction: Integrated security ecosystems—featuring PIR sensors, vibration detectors, and AI-enabled alerts—slash theft and thermal incidents by 70%, significantly enhancing site safety. Additionally, rugged hardware designs ensure 99.7% uptime even in extreme temperatures (-35°C to +75°C), thereby minimizing environmental risks. By fusing advanced sensors with durable hardware, creates a robust defense against both human threats and technical failures.

Future-Ready Compliance: Multi-protocol gateways (such as the TG451) seamlessly unify legacy systems, eliminating data silos and integration complexities. At the same time, auto-generated reports simplify compliance with EMF radiation and energy efficiency standards, reducing administrative burdens. Moreover, the architecture is fully scalable for 5G networks, rural solar-powered sites, and industrial IoT applications, ensuring adaptability to evolving industry needs.

Comment