IoT Industrial Router Projects

Bivocom team recently traveled to key project regions to strengthen ties with partners, explore new market opportunities, and conduct on-site inspections of two critical deployments. The trip rigorously validated the real-world performance and scalability of two key projects. These include a 200-unit distributed IP camera surveillance system and an intelligent riverbank pump station automation project. Beyond performance checks, we gathered first-hand feedback on operational pain points and deployment needs. This reinforces our commitment to field validation and client-centric problem-solving aligned with partners’ practical requirements.

Project 1: Scalable IP Camera Monitoring

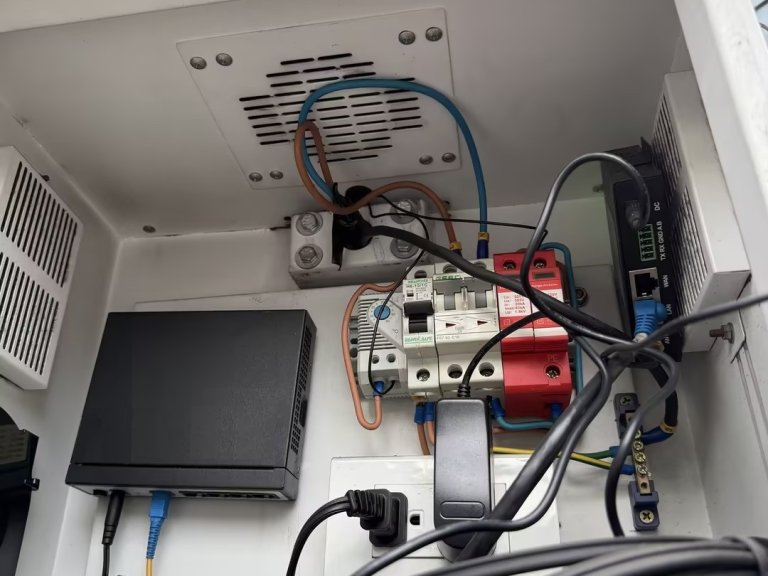

Bivocom TR321 industrial router takes center stage in a large-scale distributed monitoring project, with 200-unit deployments configurable for retail stores, outdoor stations, and industrial facilities. The solution pairs TR321 with NVRs (Network Video Recorders), switches, and IP cameras to create a cost-effective, secure surveillance network. It addresses the core pain points of distributed monitoring and delivers scalable value across diverse scenarios.

The Core Challenge

- Network Limitations: 80% of suburban or newly planned locations lack wired broadband, while consumer-grade routers can’t provide industrial-grade stable wireless connectivity.

- Scalability Bottlenecks: 200+ scattered points demand low-cost, replicable deployment—traditional industrial gateways are too expensive and bulky for mass rollout.

- Space Constraints: Compact enclosures (e.g., 0.02m³ traffic pole boxes, retail low-voltage cabinets) cannot accommodate large industrial equipment.

- Harsh Environment Vulnerability: Extreme temperatures, dust, and humidity cause consumer-grade routers to fail.

- Data Security & Continuity Risks: Sensitive surveillance footage (e.g., traffic violations, pedestrian trajectories) risks leaks over public networks; network outages threaten data loss without local backup.

- Heavy O&M Burden: On-site inspections and troubleshooting for 200+ devices consume 30% of project budgets, with slow fault resolution delaying operations.

The Solution Logic: TR321 + NVR + Switch

Core Value: Quantifiable Gains for Users

Project 2: Pump Station Automation

The Bivocom TR341 IoT Industrial Router acts as the connectivity backbone. It seamlessly integrates RTU, PLC, HMI, water level sensors (analog input), and gauges to enable unmanned pump station operations. This smart system aligns with best practices from AMR Asia, a renowned industrial automation provider. It transforms manual, high-risk riverbank pump management into intelligent, data-driven infrastructure.

The Core Challenge

- Operational Inefficiency & High Costs: 10-30 minute on-site response times cause delayed pump activation (overflow/flood risks or insufficient drainage); ±10cm gauge errors trigger energy waste or equipment overloading; 24/7 manual shifts consume 40% of annual budgets, with staff turnover risking disruptions.

- Safety & Unattended Vulnerabilities: Rainy/nighttime operations raise slip/fall/electrical hazards (increasing liability costs), while unmonitored periods (nights/holidays) leave pump failures or extreme water levels undetected.

- System & Environmental Limitations: Complex integration requires extra hardware/wiring; harsh outdoor conditions (-20℃ to 60℃+, humidity, dust) lead to rapid failure of non-industrial-grade equipment.

- Data & Remote Management Gaps: Lack of historical operational data hinders troubleshooting, optimization, and compliance; no secure remote access forces costly on-site visits for even minor adjustments.

The Solution Logic: TR341 + RTU + PLC + HMI

The TR341 acts as the “neural hub,” seamlessly connecting water level sensors (analog input), RTU, PLC, HMI, and switches. RTU converts analog water level data to digital signals, which the TR341 forwards to the PLC—triggering DI/DO modules to auto-start/stop pumps based on preset thresholds. The TR341 syncs data to the HMI for local visualization. It also links to switches to transmit on-site camera feeds to remote platforms. This enables “data + visual” dual monitoring.

Every native TR341 feature maps directly to the pump station’s needs, turning hardware into tangible solutions:

Core Value: Quantifiable Gains for Users

The TR341 core strengths—5-port connectivity, network redundancy, industrial durability, and cost-effectiveness—deliver transformative benefits. Its flexibility brings to life “One Solution, Multiple Applications.” Examples include mobile pump stations (GPS-enabled asset tracking for temporary flood control), wastewater treatment plants (sensor integration via Modbus and dual SIM redundancy), and agricultural irrigation pumps (low-power 4G for scheduled control).

In essence, the TR341-powered solution unifies discrete industrial devices into an intelligent, unmanned ecosystem. This transformation turns labor-heavy, high-risk pump operations into proactive water management infrastructure. Balancing industrial reliability, seamless connectivity, and cost-effective scalability, Bivocom redefines secure, efficient connectivity for critical water management applications.

About Bivocom

Our reliable, cost-effective industrial routers enhance efficiency, safety and scalability. Reach out to [email protected] for a free customized assessment to fuel your smart innovation. We advance relentlessly with a partner-centric focus. Our IIoT expertise powers a greener, smarter and safer connected ecosystem, standing with you throughout every innovation journey.

Comment