With the development of technology, power inspection robot is widely used in various industries. For example, in industrial production, building maintenance, traffic management, security monitoring, as well as healthcare, intelligent inspection robots are used. Therefore, intelligent power inspection robot is required in many different industries and plays an important role in today’s society.

As an expert in the intersection of the robotics and electric power industries, Bivocom keeps up with the trend by independently developing a highly reliable 5G gigabit gateway TG463, which is applied to the solution of intelligent inspection robots for the electric power industry. The goal is to create industry applications that are mathematized, intelligent, and unmanned, promoting the intelligent upgrade of electric power inspection.

Analysis of Pain Points

- Traditional manual inspections are greatly affected by time, weather, and manpower constraints. The inspection scope is large, and the detection methods are single, and it is difficult to conduct accurate inspections in harsh environments, resulting in low operational efficiency.

- Electric power belongs to a high-risk field, with a high accident rate, especially during the operation and maintenance of the power grid, accidents often pose a major threat to workers’ safety, and there are many blind spots.

- Data cannot flow freely and be shared between different levels and departments, forming data silos, which seriously hinders the integration and analysis of electric power data, resulting in untimely response.

System Solution

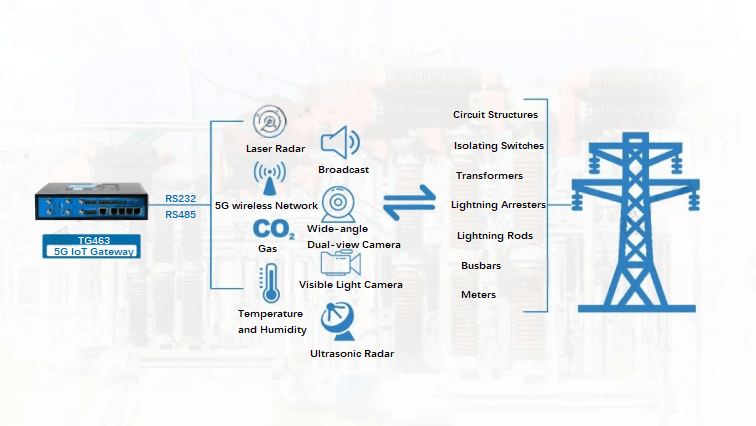

The main solution of the Bivocom power intelligent inspection robot is to install the 5G Gigabit Gateway TG463 in the power intelligent inspection robot or unmanned aerial vehicle equipment. It uses its own 5G gigabit network to monitor and collect on-site video, image, voice, etc., automatically completes detection, cruising, data recording, remote alarm confirmation, realizing the digitization, intelligence, and mobility of the intelligent inspection robot. After the data collection is completed, the relevant power grid data will be transmitted back to the Power Intelligent Inspection Monitoring Platform in real-time through the 5G network, and the platform system will carry out AI image recognition, video analysis, and other data integration and algorithm processing to obtain comprehensive inspection results, effectively improving the safety level, inspection efficiency, and security effectiveness.

It is worth mentioning that the Power Intelligent Inspection Robot can also perform remote preset time and task execution for intelligent inspections with the assistance of the 5G Gigabit Gateway TG463, and carry out 24/7 inspections. Management personnel do not need to be on-site, they only need to respond to alarm data in a timely manner on the monitoring platform.

Products Functions

-

Intelligent Inspection

By equipping the 5G gigabit gateway TG463 with sensing devices such as laser radar, 5G wireless networks, gas detectors, temperature and humidity sensors, infrared thermal imaging cameras, broadcasting voice systems, wide-angle dual-view cameras, visible light cameras, and ultrasonic radars. It can real-time monitor power station elements such as circuit structures, breakers, isolating switches, transformers, lightning arresters, lightning rods, busbars, and meters. This enables all-weather and automated intelligent inspection, which can timely detect potential hazards and eliminate the dangers of manual inspections.

-

One-click Alarm

During the inspection process, if any anomalies are detected, the power intelligent inspection robot will immediately send out an alarm signal and send a warning message to the platform management personnel.

-

Video Recognition

Utilizing the TG463’s high-precision image recognition algorithm, accurate identification of various meters such as power meters, plates, switches, indicator lights, equipment appearances, etc. is achieved, and automatic reading is carried out. This automatically completes repetitive and laborious, as well as hazardous work content, comprehensively grasping the information of the power equipment and environment within the station.

-

Infrared Temperature Measurement

By accessing the infrared thermal imaging camera through the TG463, real-time collection of the temperature of power equipment is achieved, ensuring that the high-density and high-granularity temperature data of the distribution room equipment and environment are within the normal range.

Comment