Unlocking the Future of Energy

All-in-One C&I Energy Storage Cabinet

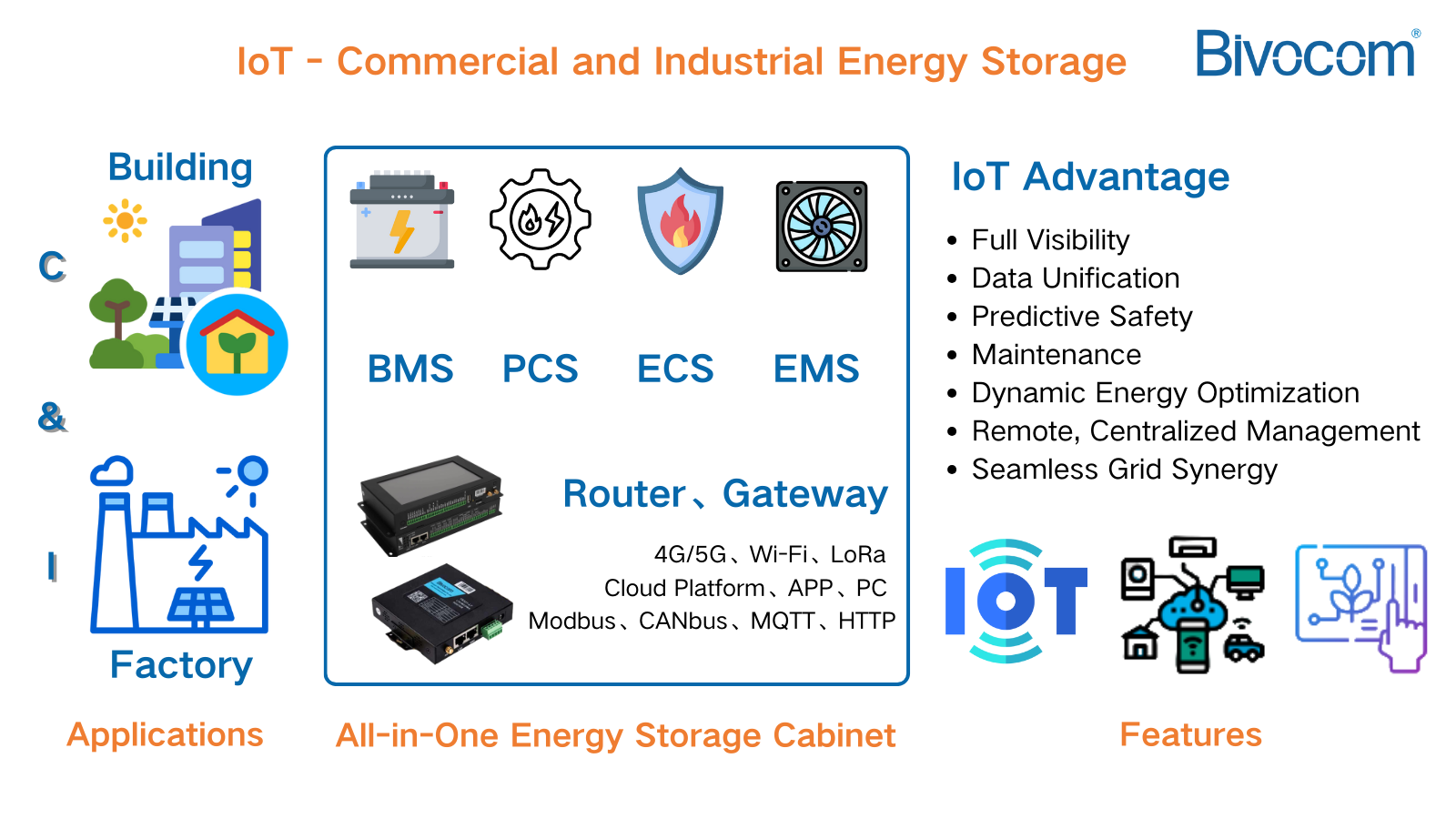

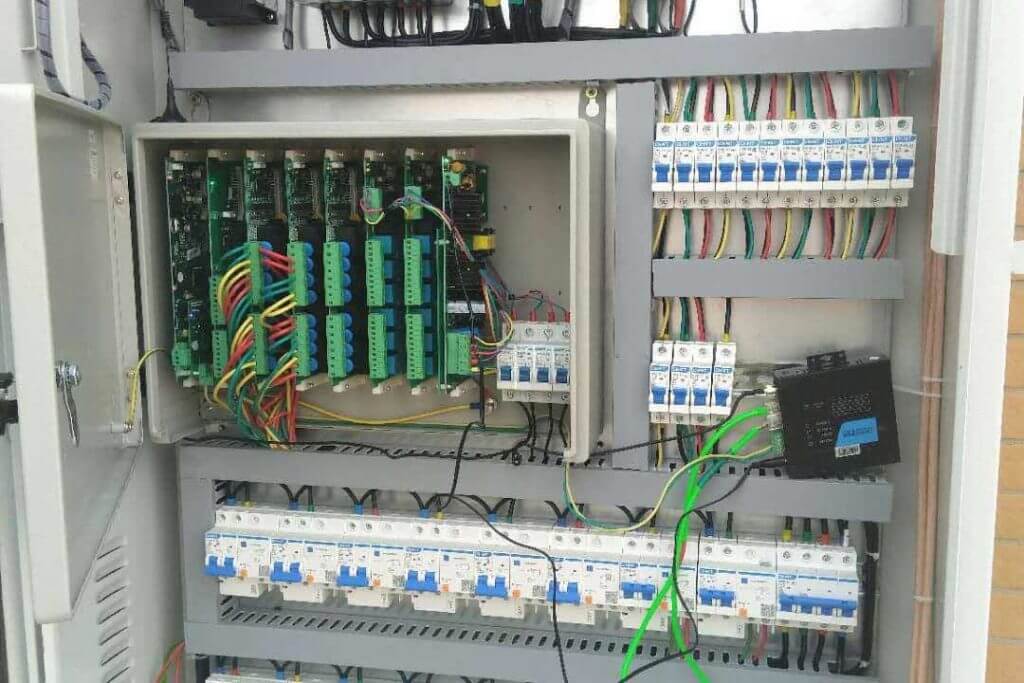

At its heart, All-in-One Commercial and Industrial (C&I) Energy Storage Cabinet is a prefabricated energy storage solution that packs all critical BESS components—batteries, BMS (Battery Management System), PCS (Power Conversion System), EMS (Energy Management System), fire protection, and thermal management—into a single standardized cabinet. Designed specifically for commercial and industrial users, it’s a “one-box” answer to energy storage needs, ready to deploy right out of the factory.

This shift towards integration is driven by clear market needs. Traditional, custom-built storage systems require complex on-site assembly. This process is time-consuming, costly, and can lead to compatibility issues. As businesses seek faster ROI, enhanced safety, and operational simplicity, the All-in-One C&I Energy Storage Cabinet meets these needs with a true plug-and-play solution. It delivers significant advantages:

- Faster Deployment: 1-2 days on-site setup (vs. weeks for scattered systems)

- Lower Costs: 8-12% total system cost reduction (hardware/wiring/installation)

- Higher Efficiency: 90%+ round-trip efficiency (vs. 82-85% for disjointed setups)

- Space-Saving: 30-40% smaller footprint for space-constrained sites

- Safety & Reliability: Factory-tested component synergy (BMS/fire/thermal management)

- Scalable Flexibility: Add cabinets to expand capacity as needs grow

However, the physical integration of hardware is only part of the solution. Even the most advanced C&I Energy Storage Cabinet faces intrinsic challenges. Key concerns include ongoing battery health and safety monitoring, optimizing energy dispatch for maximum financial return, and the practical difficulties of managing distributed assets efficiently. Without intelligent oversight, these cabinets risk operating below their potential, unable to dynamically respond to changing energy prices or proactively prevent issues.

IoT Advantage

The gap between physical capability and operational intelligence is precisely where IoT technology creates transformative value, turning a static cabinet into a smart, connected asset. IoT acts as its nervous system and brain. By connecting sensors, gateways, and cloud platforms, it solves core problems and creates a decisive competitive edge.

Bivocom Tailored IoT Products & Solutions

In the competitive C&I energy storage sector, reliable connectivity and edge intelligence are essential. Through in-depth industry needs analysis, Bivocom has developed and validated robust, industrial-grade IoT solutions. These solutions span diverse countries, sectors, and equipment types. Their core mission? To solve key challenges in deployment, security, and control. Take two of our flagship products as examples. The TG462S serves as the “smart brain”—powering edge processing and local control. The TR321 acts as the “stable backbone”—delivering secure, cost-effective connectivity. Below is a detailed breakdown of each product’s unique value, technical capabilities, and tailored solutions for C&I energy storage cabinets.

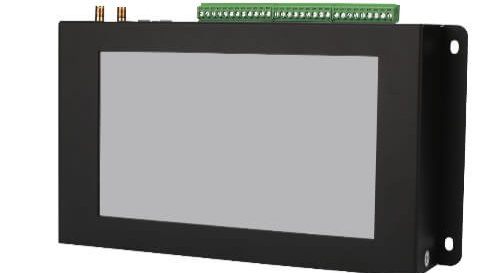

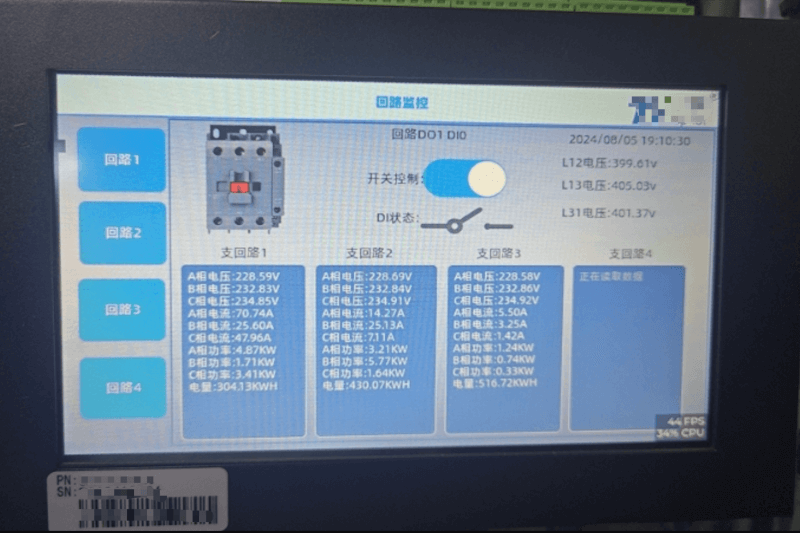

TG462S Touch Screen IoT Edge Gateway

The TG462S integrates powerful local computing and extensive connectivity. It functions as both a data aggregator and an on-site controller, processing critical information locally to execute safety and grid responses in under 50ms. With its optional 7‑inch touch screen (800×480 HD, customizable UI), operators can monitor and control the system directly at the cabinet, enabling intuitive interaction and immediate troubleshooting.

- Processing & Storage: 32-bit ARM Cortex A7 (528MHz); 256MB DDR3; 256MB–1GB Flash (1GB standard for TG462S); Micro SD support (up to 32GB)

- Interfaces: 4xRS232, 3xRS485, 8×12-bit ADC (4-20mA/0-5V), 4xDI, 4xRelay (5A/30VDC); 2xRJ45 (10/100Mbps)

- Networking: Optional LTE CAT4/CAT6; Wi-Fi (802.11b/g/n); VPN (IPsec/OpenVPN/PPTP)

- Software & Programmability: OpenWrt-based; supports Python/Node-RED/LUA for edge logic; Modbus RTU/TCP, MQTT, custom protocols

- Reliability: -35°C to +75°C operating temperature; IP30 protection; hardware/software watchdog

Integration & Outcomes

TR321 Industrial Router

While the TG462S delivers advanced intelligence, the TR321 Industrial Router focuses on providing secure, cost-effective connectivity. Compact and rugged, its core advantage lies in an optimal balance of reliability, simplicity, and affordability. It strips away unnecessary complexity while retaining all critical features for energy storage: stable cellular connectivity, protocol compatibility, and industrial-grade durability.

- Interfaces: 1xRS232, 1xRS485, 2xRJ45

- Networking: 4G LTE/CAT M1/NB-IoT options; optional Wi-Fi—adapts to weak or remote network conditions

- Physical Design: 100×100×23mm compact design; DIN rail/wall mount

- Reliability: 35°C to +75°C operating temperature; metal housing; 5-35VDC wide voltage input; VPN support (IPsec/PPTP/L2TP/OpenVPN) + firewall

Integration & Outcomes

Future: Connected & Self-Optimizing Ecosystem

About Bivocom

Bivocom leverages deep Industrial IoT expertise and a global footprint to provide reliable connectivity for critical energy infrastructure. We integrate rugged hardware (GNSS/LoRa/5G routers, gateways, and RTUs) with adaptable software platforms, directly addressing key challenges in the energy sector. Our solutions transform standalone C&I Energy Storage Cabinets into intelligent, data-driven nodes within a wider energy network.

Ready to elevate your energy storage intelligence?

Bivocom IoT solutions enhance safety, scalability, and profitability for your energy storage projects. Reach out to [email protected] for a free customized assessment and take the first step toward a greener, smarter energy future.

Comment