Powers Smart Grid Transformation

The global demand for electricity is soaring—driven by urbanization, industrial growth, and the rise of renewable energy. Substations, the backbone of power grids, face mounting pressure to balance efficiency, reliability, and adaptability. According to the IEA, 70% of transmission transformers in developed countries are operating beyond their design life, while renewable integration adds volatility to grid operations. This is where Substation IoT Solutions come in—and Bivocom, a leading IoT/M2M provider, is at the forefront of delivering smart connectivity that solves these critical challenges.

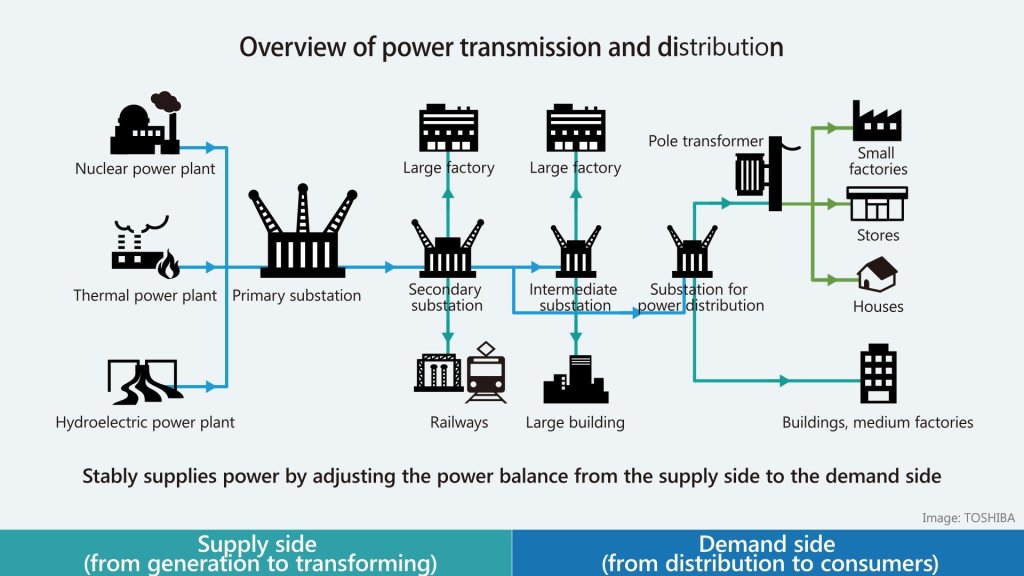

A substation is a vital link in the power chain, acting as a “power hub” between power plants, transmission lines, and end users. Its core role is to adjust voltage levels—stepping high-voltage electricity down for safe distribution or stepping low-voltage up for long-distance, low-loss transmission. Without substations, the electricity generated at power plants (or from solar/wind farms) couldn’t reach homes, factories, or businesses safely.

- Voltage Transformation: Converts high-voltage power (e.g., 220kV) from transmission lines to medium (10kV) or low-voltage (0.4kV) for end use, and vice versa.

- Power Regulation: Maintains grid stability by balancing voltage, frequency, and power factor (PF) to avoid fluctuations.

- Protection & Isolation: Uses circuit breakers and relays to quickly isolate faults (e.g., short circuits) and prevent widespread outages.

- Power Flow Control: Directs electricity to high-demand areas, ensuring efficient distribution across the grid.

- Transmission Substations (≥110kV): Connect power plants to regional grids for long-distance transmission.

- Distribution Substations (≤35kV): Supply electricity to residential, commercial, and industrial areas.

- Renewable Grid-Connected Substations: Adapt power from solar/wind farms for grid integration.

- Indoor/Outdoor/Box-Type Substations: Designed for different space and environmental needs (e.g., urban centers vs. rural areas).

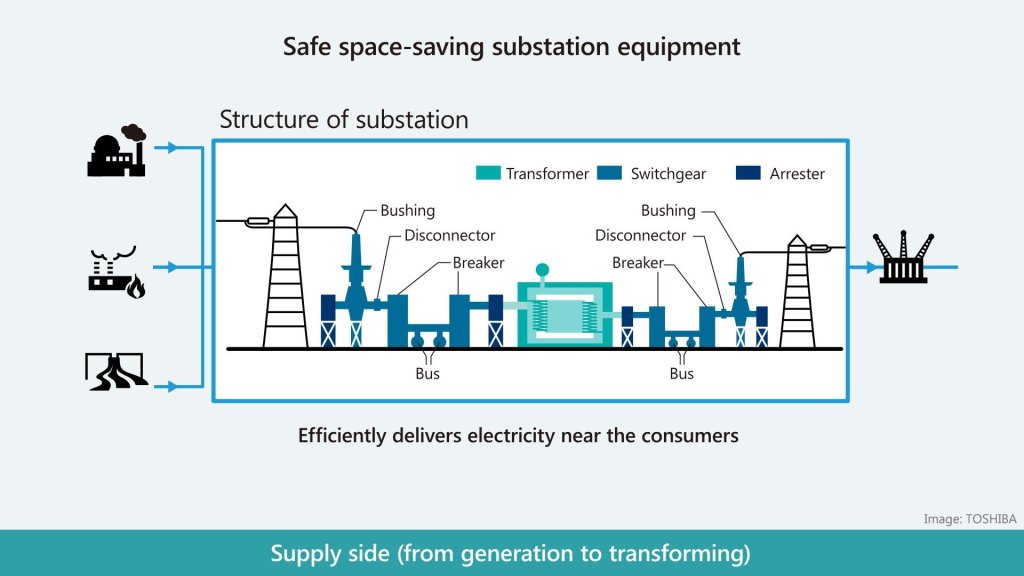

- Transformers: The “heart” of voltage conversion.

- Circuit Breakers & Isolators: Ensure safe fault isolation and maintenance.

- Capacitors: Compensate reactive power to improve efficiency.

- Protection Relays: Detect abnormalities and trigger quick responses.

- Control Systems: Manage operations via SCADA (Supervisory Control and Data Acquisition).

Modern substations face interconnected challenges that strain grid resilience. Aging equipment drives frequent failures and steep maintenance costs, while renewable (solar/wind/water/…) integration compounds volatility. Manual, time-consuming inspections are obsolete—real-time monitoring has become a critical need. Cybersecurity risks persist, and fragmented communication protocols hinder seamless system coordination. Adding to this, there’s mounting pressure to reduce carbon emissions and streamline operational expenses.

IoT technology turns traditional substations into “smart substations” by adding connectivity, data visibility, and automation. By integrating sensors, gateways, and cloud analytics, IoT addresses core challenges and unlocks new value:

- Real-Time Monitoring & Diagnostics: Sensors track equipment status (temperature, vibration, oil levels for transformers) and environmental conditions (humidity, SF₆ leakage). Data is transmitted instantly to operators, eliminating blind spots.

- Predictive Maintenance: AI-powered analytics turn raw data into actionable insights—predicting equipment failures before they occur. This replaces costly “break-fix” or scheduled maintenance with targeted, efficient upkeep.

- Enhanced Safety: IoT enables remote monitoring and control, reducing the need for on-site personnel in high-risk areas. Automated alerts for hazards (e.g., gas leaks, overvoltage) further minimize safety risks.

- Grid Optimization: IoT synchronizes substation operations with renewable energy output and demand patterns. This improves renewable energy absorption rates and reduces grid congestion.

- Cost Reduction: By cutting downtime, optimizing maintenance, and improving energy efficiency, IoT-driven substations lower operational costs by 30-50% (per industry benchmarks).

Bivocom brings over 10 years of IoT/M2M expertise to substation connectivity—with products designed to withstand harsh industrial environments, support critical protocols, and deliver uninterrupted performance. Here’s how our products empower smart substations:

The TD210 is an industrial cellular modem designed to enable secure, reliable connectivity for substation serial devices (sensors, PLCs, meters) via global cellular networks, bridging legacy hardware to cloud or SCADA systems for real-time monitoring and control. It’s ideal for real-time monitoring of transformer temperature, circuit breaker status, energy meters, and power consumption.

Key Advantages:

- Robust Performance: Built-in industrial MCU and multi-layer software/hardware protection mechanisms ensure stability in substation environments; LED indicators (Online/Act/Power/System) simplify status monitoring.

- Flexible Connectivity: Global 4G/3G/2G compatibility and dual serial ports (1-RS232, 1-RS485) adapt to diverse substation legacy equipment.

- Seamless Data Transmission: Supports transparent transmission, Modbus RTU/MQTT(No TLS)/TCP/UDP, and Modbus-to-JSON over MQTT/CSD for hassle-free integration.

- Redundant Data Backup: Syncs data to up to 5 centers, preventing critical operational data loss.

- Easy Management: Visual config tool, AT Command, and SMS remote management (Cloud DMP optional) reduce on-site maintenance effort.

- Space-Saving Design: Compact metal housing (91x58x22mm, 208g) with wall-mount fits space-constrained substation cabinets.

The TR341 is a cost-effective industrial router that centralizes connectivity for substation Ethernet and serial devices (like protection relays, video surveillance cameras, environmental monitors), serving as the core network hub for SCADA systems, ensuring seamless data flow between on-site equipment and remote control centers, even in high-interference grid environments.

Key Advantages:

- Comprehensive Connectivity: 5 Ethernet ports (1-WAN/4-LAN) and dual serial ports (1-RS232, 1-RS485) for substation’s multi-device ecosystem (sensors, cameras, relays)

- Flexible Network Compatibility: Options for 4G LTE CAT6/CAT4/3G/2G, WiFi (IEEE 802.11b/g/n, up to 300Mbps), and independent GPS enable deployment in diverse substation scenarios.

- Redundant Reliability: Optional dual SIM for failover and auto-switching between WWAN/WAN ensure 24/7 connectivity.

- Enterprise-Grade Security: RADIUS WiFi authentication and VPN tunnels (IPsec/PPTP/L2TP/GRE/OpenVPN) safeguard sensitive grid data.

- Protocol Support: Native Modbus RTU/TCP, MQTT, SNMP, RIP, and OSPF alignment with substation control system standards.

- Easy Deployment: Desktop/wall-mount metal housing (168x104x27mm, 790g) and intuitive status LEDs simplify installation and monitoring.

The TG452 is a high-performance edge gateway based on Openwrt, designed to collect, process, and store substation data locally while connecting legacy and modern equipment to the cloud. It’s designed for time-sensitive substation tasks like transformer vibration analysis, voltage fluctuation detection, and predictive maintenance—where low-latency decision-making is critical for grid stability.

Key Advantages:

- Powerful Hardware: 32-bit ARM Cortex A7 (528MHz) CPU, 256MB DDR3 memory, and 256MB flash (extendable to 1GB) support local edge computing.

- Rich I/O Versatility: 4-RJ45, 2-RS232, 3-RS485, 2-DI, 2-Relay (5A/30VDC-250VAC), 2-ADC (4-20mA/0-5V), optional CAN, and TF card slot (up to 32GB) cover all substation device connection needs.

- Flexible Connectivity: Global 4G LTE CAT6/CAT4/3G/2G/LTE M1/NB-IoT compatibility; optional dual SIM/dual module for failover/load balance and WiFi/GNSS.

- Advanced Programmability: Supports C/C++/Python/Node-RED/LUA programming and SDK/API, enabling custom substation-specific analytics.

- Secure & Resilient: VPN tunnel encryption complies with grid security standards; local data logging during network outages preserves critical insights.

- Smart Integration: Modbus RTU-to-TCP conversion facilitates IEC 61850 smart grid compatibility; desktop/DIN-rail mounting fits standard substation panels.

All three products are purpose-engineered for substation environments, featuring -35°C to +75°C operating temperature resilience, IP30-rated metal housing to withstand electromagnetic interference and voltage fluctuations, and a wide 5-35VDC input voltage to adapt to unstable substation power supplies. Global cellular network compatibility ensures deployment flexibility across urban, rural, and remote sites, while 2-5 year warranty options reflect Bivocom’s commitment to long-term reliability—lowering total cost of ownership for grid operators and ensuring a resilient connectivity backbone for smart substations.

Bivocom boasts proven success in key energy sectors leveraging industrial-grade hardware, multi-protocol compatibility, and scenario-specific solutions. Tailored for complex industrial environments, its offerings focus on core needs like data collection, remote monitoring, and intelligent scheduling—proven reliable in real deployments.

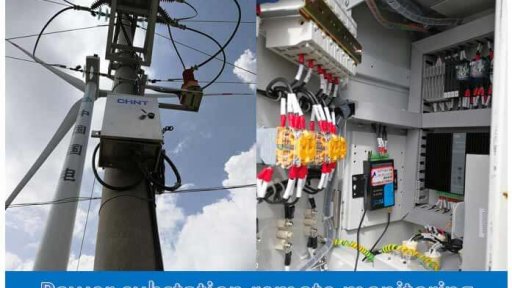

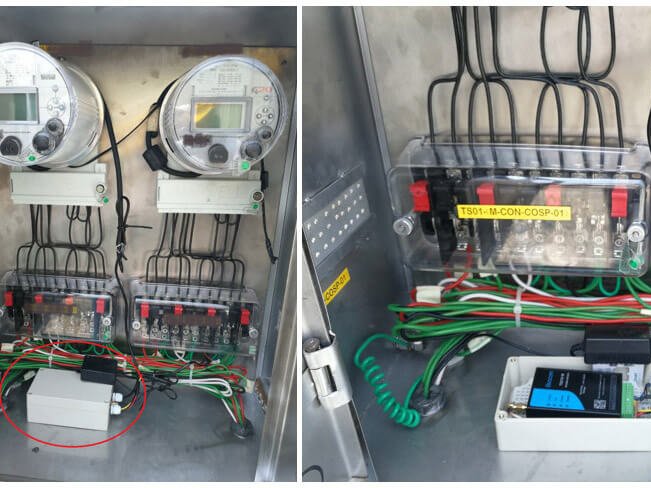

Bivocom collaborates with a leading wireless module supplier to deploy its TD210 cellular modems in Southeast Asian smart grid projects, replacing legacy GPRS modems for automatic meter reading (AMR). The solution supports global frequency bands and Modbus protocol, with over 2,000 units successfully field-deployed. Its TR321 router was selected for Singapore’s smart metering projects, connecting Schneider PM2230 meters via RS485 interfaces to transmit consumption data to MQTT cloud platforms, enabling remote monitoring for parking lots, residential areas, and commercial complexes.

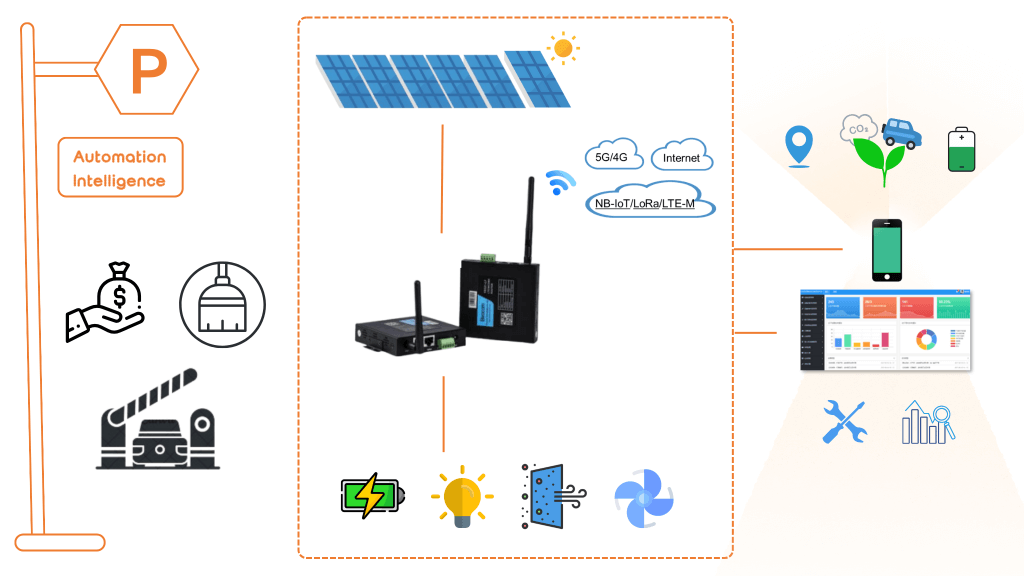

Leveraging LTE-M/

NB-IoT wireless technology, Bivocom integrates industrial-grade devices to deliver remote management solutions for off-grid and geographically

dispersed substations. The cost-effective, energy-saving offering addresses power companies’ core pain point of difficult on-site maintenance for remote assets, ensuring stable connectivity and real-time operational visibility.

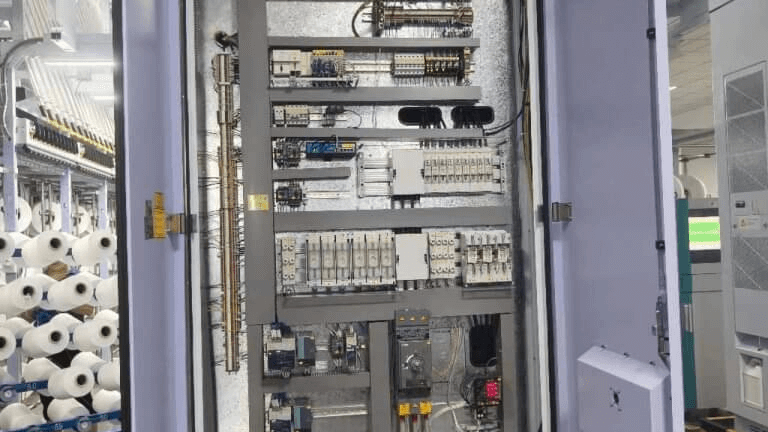

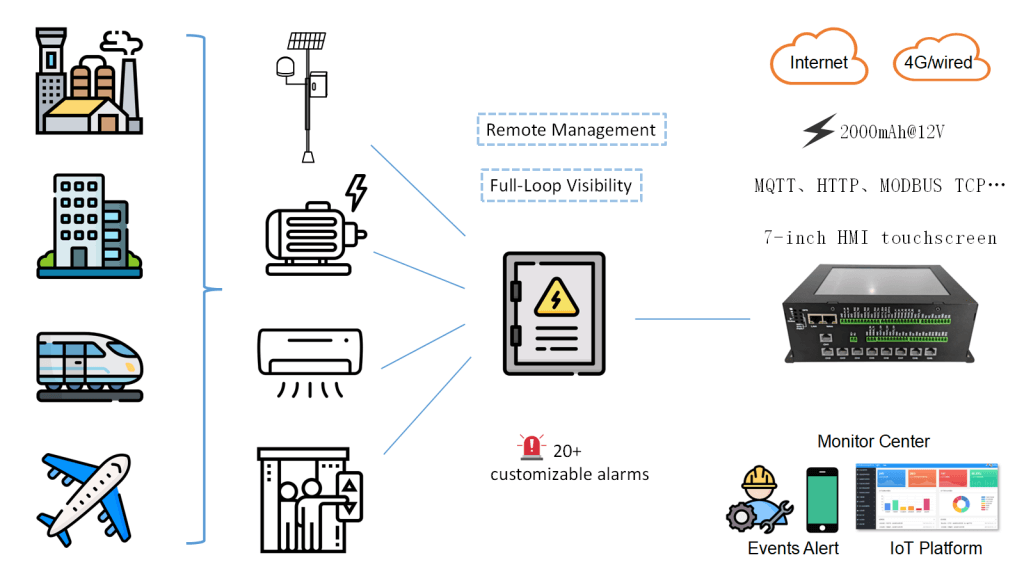

Bivocom TG462S intelligent controller empowers lighting distribution cabinets with circuit monitoring and remote management capabilities, supporting 4G/wired dual communication and customizable alarm triggers to reduce fault response time from hours to minutes. Its routers/modems/gateways transform conventional electrical panels into smart energy hubs, enabling real-time tracking of voltage, current, and other key parameters, as well as predictive maintenance, which cuts energy waste.

Bivocom TR321 routers provide end-to-end monitoring for on-grid and off-grid solar power systems, collecting performance data from panels, inverters, and energy storage devices to optimize generation and consumption efficiency. For the EV and renewable energy ecosystem, its TR321/TR341 industrial routers power smart EV charging stations and solar-integrated parking lots, supporting remote device management and dual-network redundancy to ensure reliable operation, aligned with global net-zero transition goals.

As grids evolve toward decarbonization and decentralization, three trends will shape substation IoT:

- Tech Evolution: All-optical networks (10Gbps bandwidth) and quantum tech (precision sensing, secure encryption) will scale. Digital twins enable virtual-real operations and self-healing, while edge AI handles on-site analytics. Zero-trust security becomes hardware-embedded.

- Commercial Value: Data-as-a-Service (DaaS) and reliability-based pricing drive new revenue. Substations act as VPP aggregation hubs, with green finance access via IoT efficiency data.

- Policy & Ecosystem: IEC 61850-90-5 standard unifies by 2027 for plug-and-play compatibility. Cross-border tech recognition and skill-building programs support adoption, with green bonds funding upgrades.

Bivocom brings over a decade of industrial IoT expertise and a footprint in 90+ countries, focusing on empowering grid modernization through tailored substation IoT solutions. We address core substation challenges—aging infrastructure, renewable integration volatility, inefficient manual operations and maintenance, and cybersecurity risks—for utilities, grid operators, and industrial energy managers. Our integrated offering combines rugged hardware (

GNSS/LoRa/5G routers, gateways, and RTUs),

IoT/EMS cloud platforms, and scenario-specific

sensors, transforming reactive substation operations into proactive, intelligent management aligned with global energy transition goals. Core Strengths:

- Scenario-Adapted: Tailor solutions for urban/remote substations, renewable grid connections, and legacy equipment upgrades.

- End-to-End Intelligence: Unify real-time data collection, edge analytics, predictive maintenance, and secure remote control for closed-loop grid management.

- Global-Local Synergy: Leverage global deployment experience to adapt proven IoT technologies to regional grid standards and operational needs.

![[Case Study] Bivocom Smart Pole TG451 & Sensors](https://www.bivocom.com/wp-content/uploads/2026/09/Case-Study-Bivocom-Smart-Pole-TG451-Sensors-768x512.png)

2 Comments