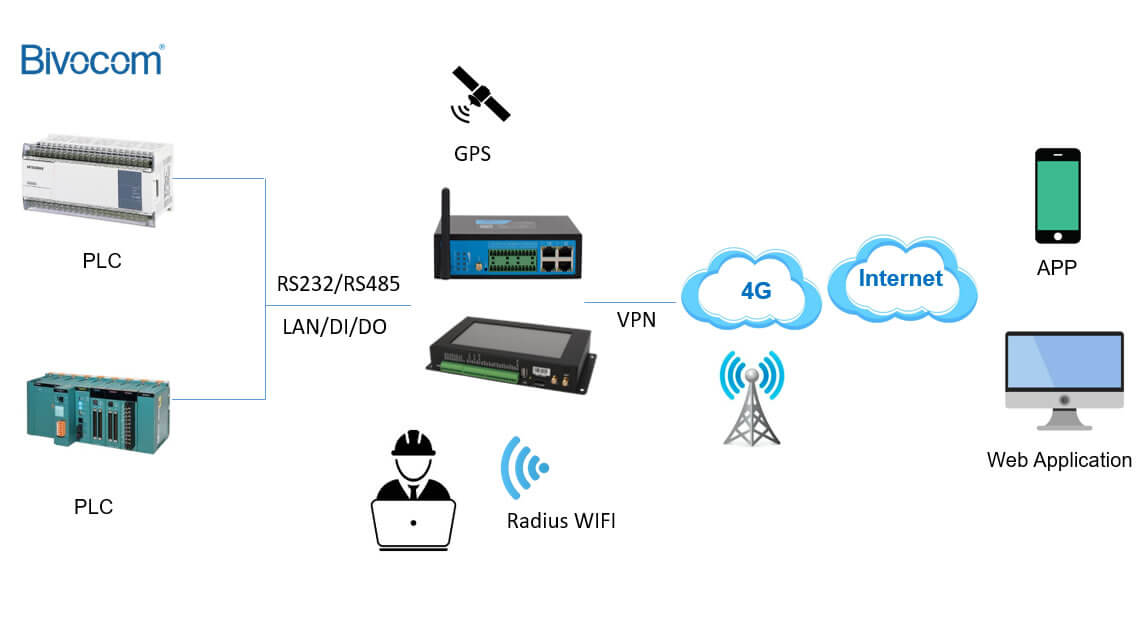

One of the industrial PLC serial gateways, which realizes the connection settings between PLC and gateway. The PLC serial gateway of Bivocom supports Ethernet, WIFI, 3G/4G/5G network access, supports SIM card, wired and wireless dual link backup and other functions . Realize switching between different links, built-in multi-level link detection and recovery mechanism to ensure uninterrupted device network connection. An industrial-grade smart gateway with an embedded network operating system that supports remote custom configuration, remote layout, gateway status monitoring and other skills.

PLC is called a programmable controller. The PLC control system is a new generation of industrial control device that introduces microelectronics, computer, automatic control and communication skills on the basis of traditional sequence controllers. The purpose is to replace relays. , Execute logic, timekeeping, counting and other sequential control functions to establish a flexible long-distance control system.

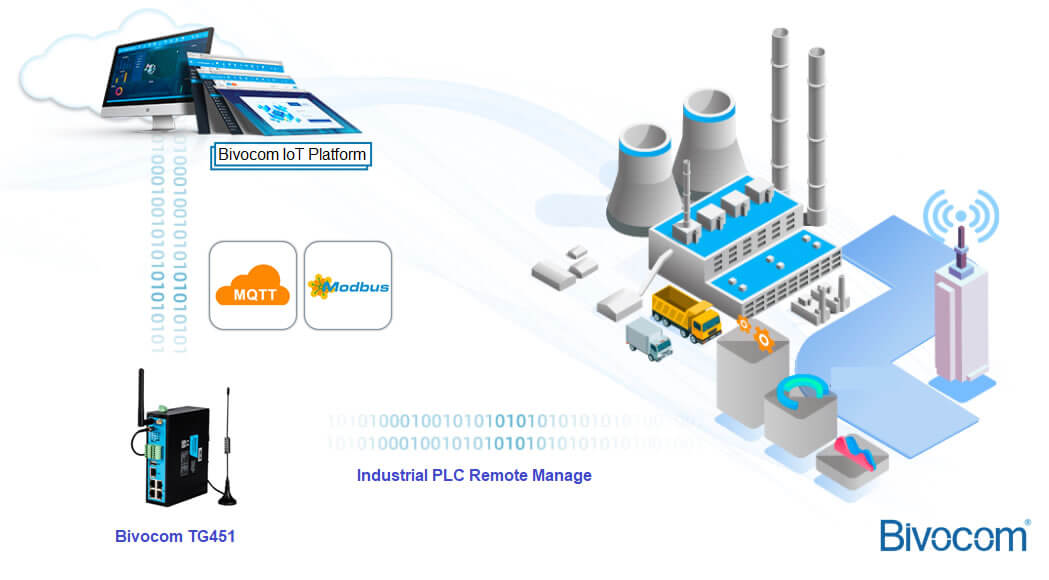

The PLC industrial intelligent serial port gateway is suitable as the access node of large-scale distributed equipment. The embedded protocol analyzer can first collect the field device data through the protocol analysis to the gateway node for calculation and analysis, and then transmit it to the customer through the MQTT Internet of Things protocol Custom MQTT cloud channel.

PLC serial gateway function

- industrial field devices remotely control;

- to achieve remote device firmware upgrade, download the program, the flexibility to access a variety of device management platform;

- industrial-site touch-screen remote control and remote configuration screen mapping;

- at the same time Remote communication with multiple PLCs or touch screens;

- protocol library rich, suitable for industrial site and remote data acquisition and transmission, remote maintenance and control equipment, large-scale industrial equipment lifecycle management, all types of communications protocol analysis and conversion of Things application scenarios.

- to achieve Siemens, Mitsubishi, Omron, Schneider, Delta, when Kymmene, and Lee, Panasonic, forever, for the sea and MODBUS series PLC and other mainstream hardware protocol parsing;

- to realize PLC remote monitoring, PLC remote programming, PLC remote debugging, PLC remote upload and download , PLC remote control, PLC data acquisition, PLC remote communication .

Comment