Revolutionizing Industrial Weighing with IoT Technology

In today’s fast-paced industrial world, efficiency and accuracy are paramount for businesses looking to stay ahead of the curve. One area that has witnessed significant advancements is industrial weighing, thanks to the integration of Internet of Things (IoT) technology. The fusion of traditional weighing systems with IoT capabilities has paved the way for a new era of smart and connected solutions that are transforming the way we measure, monitor, and manage weight in industrial settings.

Streamlined Operations and Enhanced Accuracy

Icon: https://www.flaticon.com/

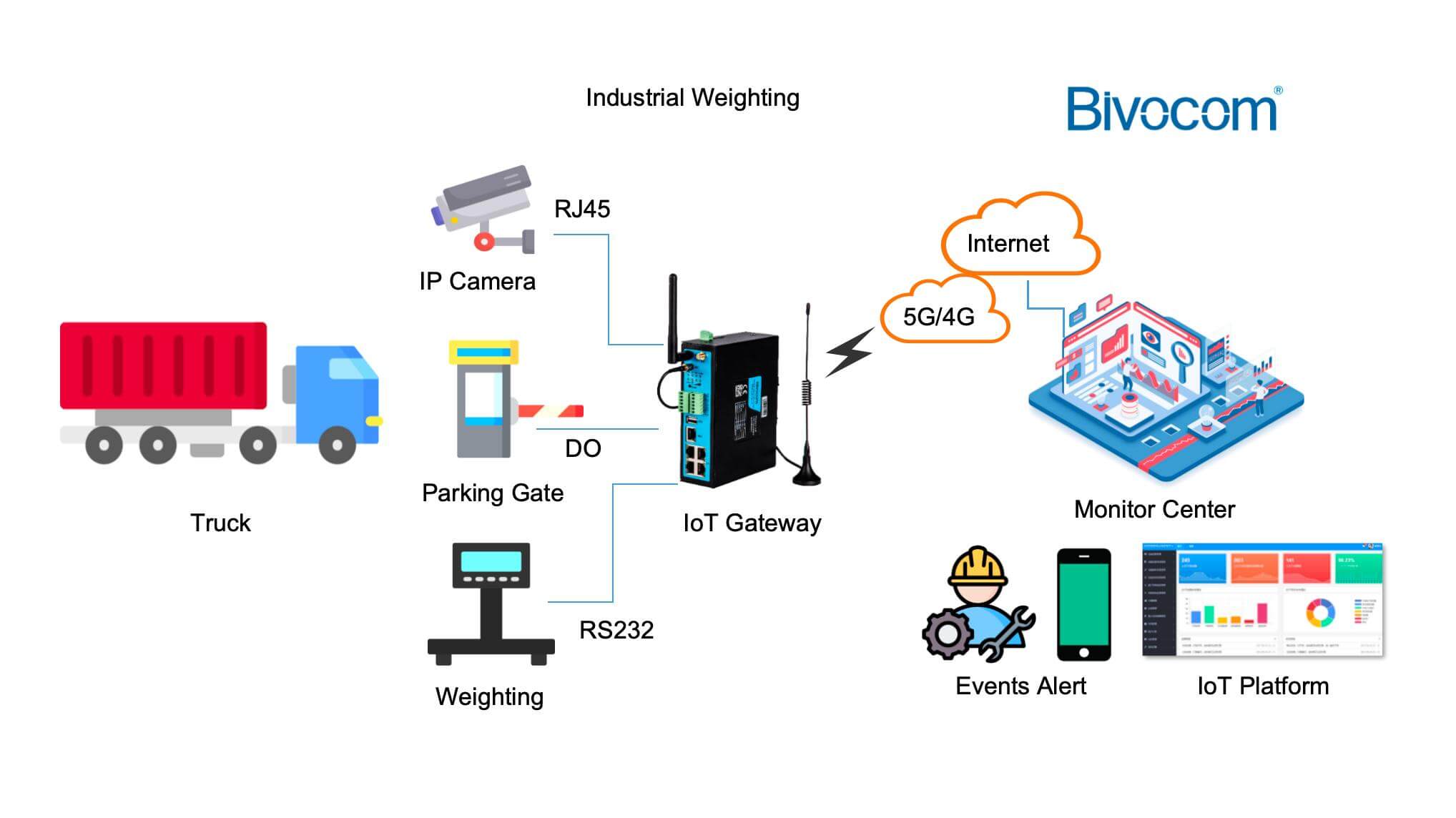

Gone are the days of manual data logging and cumbersome weighing processes. IoT-enabled industrial weighing systems have automated these tasks, streamlining operations and minimizing human error. By connecting weighing scales and devices to the internet, real-time weight data can be captured and transmitted wirelessly to centralized systems for immediate processing and analysis.

Remote Monitoring and Management

One of the key benefits of IoT technology in industrial weighing is the ability to remotely monitor and manage weighing operations. Managers and operators can access real-time weight data from anywhere, at any time, using a computer or mobile device. This level of flexibility not only enhances operational efficiency but also enables quick decision-making and proactive maintenance to prevent costly downtime.

Predictive Maintenance and Inventory Management

IoT-enabled weighing systems can also support predictive maintenance strategies by analyzing historical data and identifying patterns that indicate potential equipment failures. By detecting issues before they escalate, businesses can schedule maintenance activities proactively, reducing unplanned downtime and extending the lifespan of weighing equipment.

Moreover, integrating IoT technology into industrial weighing facilitates accurate inventory management. By automatically tracking weight measurements and syncing data with inventory systems, businesses can maintain optimal stock levels, reduce wastage, and improve supply chain efficiency.

Data Analytics and Insights

With IoT-connected weighing systems generating vast amounts of data, businesses have a goldmine of information at their disposal. Advanced analytics tools can process this data to uncover insights, trends, and performance metrics that can drive informed decision-making and operational improvements. From identifying production bottlenecks to optimizing resource allocation, data-driven insights derived from IoT-enabled weighing systems can help businesses enhance their overall performance.

Security and Compliance

While the benefits of IoT technology in industrial weighing are undeniable, ensuring data security and regulatory compliance is crucial. Robust cybersecurity measures must be in place to safeguard sensitive weight data from unauthorized access or tampering. Additionally, businesses operating in regulated industries must adhere to industry-specific standards and compliance requirements to maintain data integrity and protect customer confidentiality.

Looking Ahead: The Future of Industrial Weighing

As IoT technology continues to evolve, the potential applications for industrial weighing are limitless. From smart sensors that can detect minute weight changes to AI-powered predictive analytics that optimize operational efficiency, the future of industrial weighing is undoubtedly exciting.

In conclusion, the integration of IoT technology in industrial weighing represents a paradigm shift that is revolutionizing the way businesses measure and manage weight. By harnessing the power of connectivity, automation, and data analytics, companies can unlock new levels of efficiency, accuracy, and insight in their weighing operations, paving the way for a smarter and more sustainable industrial ecosystem.

Comment