Have you ever thought about what would happen when IoT meets geological exploration drilling? Before we talk this, let’s figure out what is geological exploration drilling, and why we need it?

What Is Exploration Drilling?

Exploration Drilling is used in the mineral mining sector to probe the contents of known ore deposits or to explore sites for potential geological/commercial value. Exploration drilling allows geologists to extract and examine sample core profiles at the surface with reduced environmental impact and lower costs.

Except mining industry, exploration drilling is also used in below industries and applications, such as

- Civil engineering

- Construction

- Water

- Oil and Gas

While as exploration drilling normally requires worker to dig drilling hole from 100 to 1,000 meters depth or more, for different applications you may need different drilling rigs.

Types of Drilling Rigs

1. Water Well Drilling Rigs

2. Mineral Exploration Drilling Rigs

3. Geotechnical Drilling Rigs

4. Multipurpose Drilling Rigs

When IoT Meets Exploration Drilling

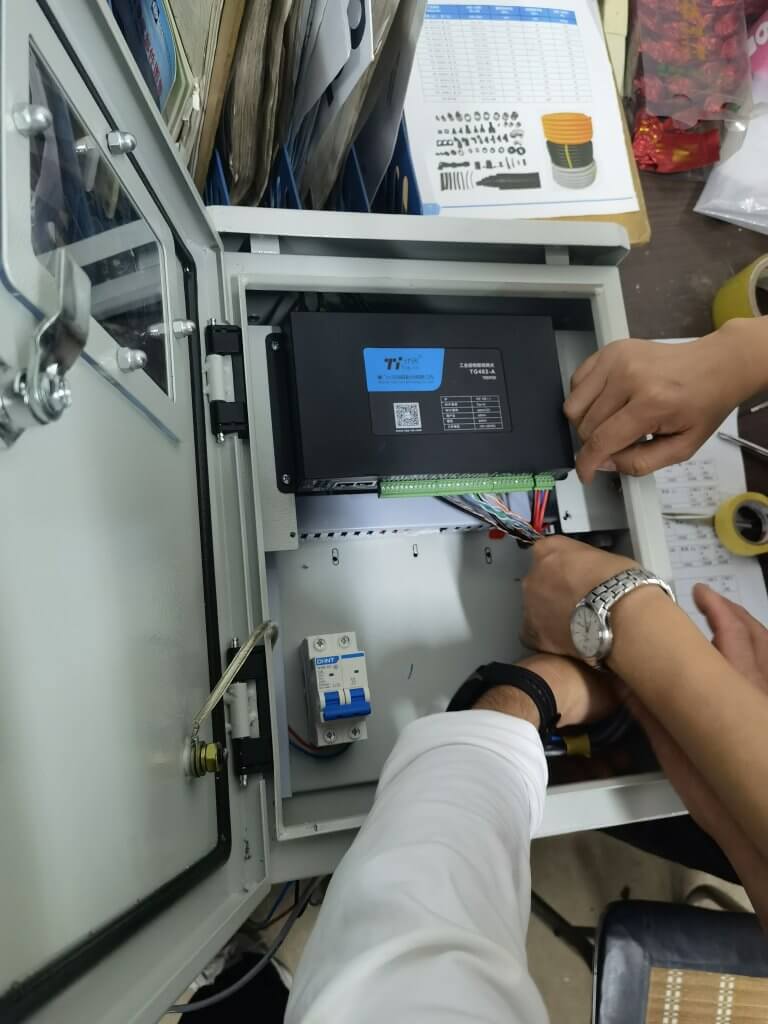

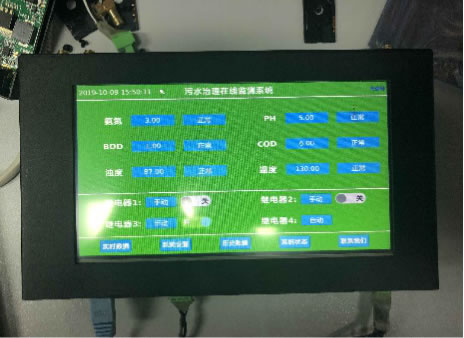

The traditional exploration drilling needs manually report data of drilling depth and status of drilling rig, which is time and labor consuming. Thanks to the IoT technology, you can connect the sensors of drilling rig to a Bivocom 4G IoT gateway, and transfer the data of drilling hole and drilling rig to remote office and control center, to reduce operating costs, increase productivity, increase utilization of equipment, reduce environmental impact, and enhance health and safety conditions.

Bivocom 4G IoT Gateway Used for Exploration Drilling

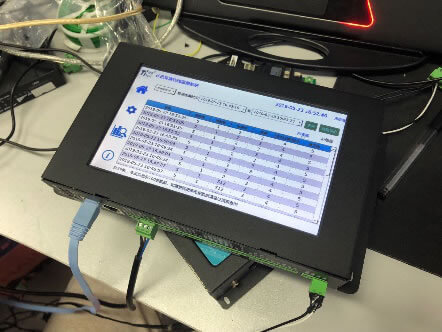

Bivocom TG462/TG462S 4G IoT Edge Gateway

- Global 4G LTE/3G/2G compliant

- 1-WAN, 1-LAN, USB, 4-RS232, 3-RS485, 1-I2C, 1-TTL, 8-ADC, 4-DI, 4-Relay, 5-Power Output, TF card slot, WIFI(Option), GPS(Option)

- OpenWRT based Linux OS, Node-Red, Python/C/C++ programmable

- 7 inch HD touch screen(TG462S only), up to 32GB local data storage

- Wide operating temperature: -35~+75 °C

- Modbus RTU/TCP, MQTT, JSON, TCP/UDP and customized industrial protocols

- Multiple VPN, SNMP, BGP, HTTP, Telnet, SSH, CLI

Useful Links

https://www.geogroup.co.za/projects/exploration-drilling/black-rock/

https://www.epiroc.com/en-au/products/drill-rigs/exploration-drill-rigs

https://www.dando.co.uk/product-categories/multipurpose-drilling-rigs/

Comment